Mechanical, Electrical, and Plumbing (MEP) systems form the backbone of modern building infrastructure. These systems are responsible for essential functions such as temperature regulation, power supply, lighting, ventilation, fire safety, water distribution, and waste disposal. Their integration and performance are fundamental to ensuring a building’s functionality, safety, and user comfort. However, coordinating these systems across architectural and structural disciplines has long been a challenge, especially when using traditional 2D drafting methods. Misalignments, spatial clashes, and inefficient layouts often result in costly rework and delays. This is where Building Information Modeling (BIM) has transformed the game. BIM offers an integrated, intelligent, and data-rich environment for MEP engineers to model, coordinate, simulate, and optimize system designs throughout the project lifecycle.

Limitations of Conventional MEP Design Workflows

Conventional MEP design often involves working in isolation, using disconnected software, and relying heavily on manual coordination. This leads to multiple rounds of back-and-forth, delays in conflict resolution, and mounting project costs. Traditional tools limit visibility into how MEP systems interact with other disciplines, resulting in frequent onsite surprises during construction.

Challenges include:

- Limited visual insight into system clashes

- Redundant or overlapping layouts

- Slow feedback between trades

- Higher probability of design errors

The inefficiency of these workflows highlights the need for a more connected and intelligent approach, which BIM provides through its collaborative platform and intelligent modeling capabilities.

BIM as a Foundation for MEP Design Excellence

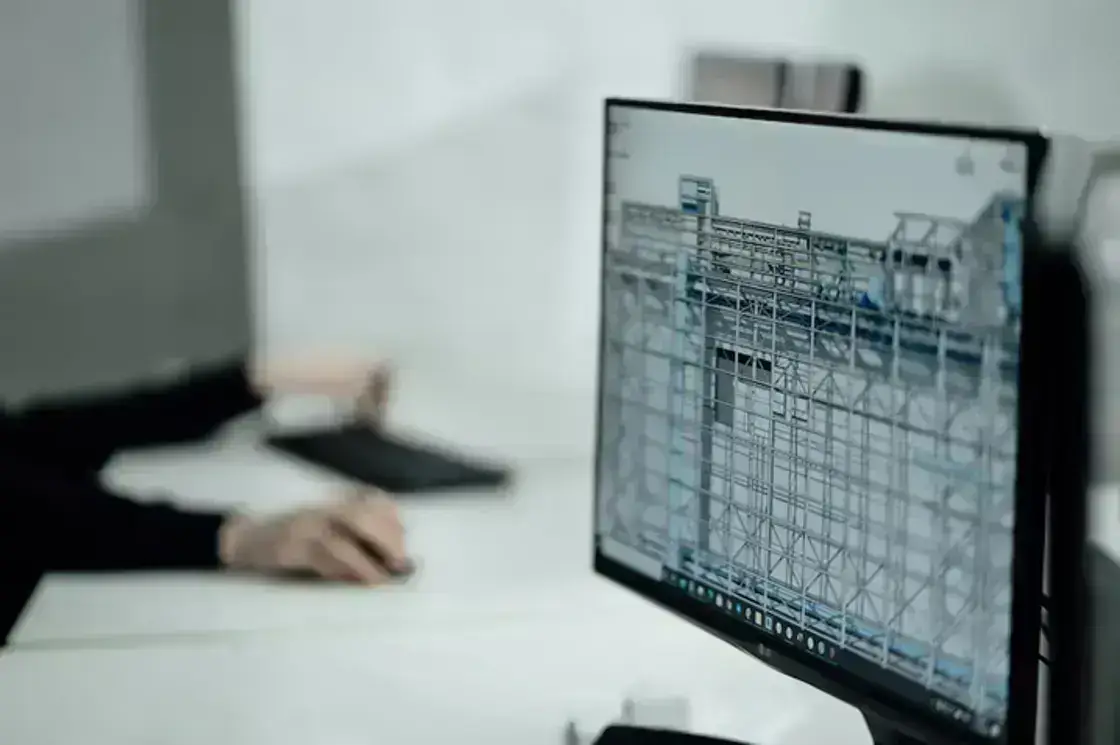

BIM brings the power of real-time, multidisciplinary collaboration into the MEP design process. Instead of working from siloed 2D drawings, BIM enables engineers, architects, and contractors to co-develop a single coordinated 3D model, rich with geometric and metadata inputs. This unified digital environment reduces rework, increases accuracy, and ensures that every system functions optimally within the spatial constraints of the building.

In a BIM ecosystem, MEP elements—whether ducts, pipes, panels, or equipment—are modeled as smart objects. These objects contain physical dimensions, performance parameters, installation data, and lifecycle information. This enables engineers to simulate, validate, and coordinate system layouts before a single pipe is installed.

Core strengths of BIM for MEP include:

- Accurate 3D visualization of all services

- Clash detection during design phase

- Quantity take-offs and cost estimation

- Lifecycle and asset management readiness

Intelligent Modeling for Smarter Coordination

One of BIM’s biggest advantages lies in its ability to integrate and validate design inputs from all disciplines. Using clash detection tools like Navisworks, design teams can run coordination checks between HVAC systems, electrical conduits, plumbing pipes, and architectural or structural components. Issues are resolved digitally, preventing conflicts onsite and dramatically reducing waste and delays.

Consider a hospital or an airport project, where space is limited and system density is high. BIM enables detailed coordination of air handling units, medical gas lines, electrical risers, and drainage systems within ceiling voids and shafts, ensuring no element obstructs another or violates clearance rules.

Coordination benefits:

- Reduces onsite rework and RFIs

- Streamlines installation schedules

- Minimizes wastage of materials

- Improves stakeholder communication

Driving Efficiency with BIM-Based Simulations

Beyond geometry, BIM tools empower MEP engineers with the ability to simulate and test system performance. Thermal loads, airflows, lighting layouts, and water usage can be modeled based on real-world parameters. This allows designers to evaluate energy efficiency, occupant comfort, and system reliability in a virtual setting—far before construction begins.

Energy modeling tools integrated with BIM (such as Insight, IES VE, or Green Building Studio) provide actionable data to support green design. Design teams can test alternate system configurations, evaluate the impact of daylighting, and determine the most efficient routing options.

Simulation use cases:

- HVAC load analysis

- Daylighting and lighting efficiency

- Pressure loss in duct and pipe networks

- Fire safety and smoke control modeling

BIM as a Centralized Data Environment

Another defining feature of BIM is its function as a common data environment (CDE). This single source of truth stores all model data, documentation, and revisions—accessible by all project stakeholders. Changes are tracked and version-controlled, providing transparency and accountability throughout the project timeline.

Every element within the BIM model contains both visual (3D) and non-visual (metadata) information. For MEP, this means that a duct not only shows its dimensions and location but also includes pressure ratings, material specifications, insulation thickness, and manufacturer references. This data becomes invaluable during fabrication, procurement, and maintenance.

Types of embedded data:

- Equipment capacity and voltage ratings

- Duct material and insulation details

- Maintenance access and installation clearances

- Asset tags for facility management integration

- Best Practices for Implementing BIM in MEP

The benefits of BIM are maximized when organizations follow structured processes, use compatible software, and invest in team training. A BIM execution plan (BEP) should clearly define the project goals, modeling standards, LOD requirements, data exchange protocols, and clash resolution workflows.

Interdisciplinary coordination meetings and federated model reviews should be scheduled regularly to catch and resolve issues in real-time. MEP engineers must work closely with architects and structural teams, ensuring system layouts align with core building geometry and usage needs.

Implementation tips:

- Develop a clear BEP early in the project

- Use LOD 300–400 for detailed coordination

- Schedule regular coordination meetings

- Choose tools that support MEP simulations and data export

Future Trends: What’s Next in BIM for MEP?

The future of BIM in MEP lies in deeper integration with emerging technologies. Artificial Intelligence (AI) is being explored to automate system layout suggestions. Internet of Things (IoT) devices are feeding operational data back into BIM models, evolving them into live digital twins. Augmented Reality (AR) and Virtual Reality (VR) are already being used for onsite inspections and training.

As buildings grow more complex and clients demand better performance data, MEP professionals must adopt these tools not just to keep up—but to lead the shift toward smarter, more efficient building systems.

Emerging innovations:

- AI-driven MEP design automation

- Digital twins for ongoing asset performance

- AR/VR for system walkthroughs

- Cloud-based model coordination and review

Conclusion

BIM is more than just a 3D modeling tool—it’s a platform for intelligence, collaboration, and continuous improvement in MEP design. By offering greater visibility, clash resolution, performance simulation, and data management, BIM transforms how MEP systems are designed, coordinated, and maintained. Engineers who embrace BIM workflows are positioned to deliver smarter designs, reduce risk, and support long-term operational efficiency. As buildings continue to evolve in complexity, BIM will remain essential for unlocking excellence in MEP engineering.

Image source: aeodc.com

.png)