Based on the quantitative criteria of building on the basis of strength, durability, versatility, and economy, steel is a universal building material.The proven performance and quality of steel have also caused it to dominate commercial interior wall framing applications for many years now. With the growing innovation the light gauge steel has continued to be used as an infill structure on multi-storey buildings built from hot rolled steel or concrete frames. Commercial and retail buildings continued to benefit from its diverse capabilities, using it as a cladding system which can be formed into many different shapes.Embracing innovation is the need of time. Lesser deadlines and economical hindrances have forced us to look out for ways that serve both time and quality, what better than a LGSF technology.

What is LGSF Technology?

Light Gauge Steel Framing (LGSF) is a construction technology that uses cold-formed steel sections to create a durable and efficient structural framework for buildings. In this approach, thin steel sheets are cold-formed into specific profiles, providing strength and flexibility. LGSF is known for its speed of construction, design adaptability, and cost-effectiveness. Prefabricated steel components are often used, allowing for quick on-site assembly. This construction method is suitable for a variety of building types, including residential, commercial, and industrial structures, and has gained popularity for its ability to meet modern construction challenges with a focus on efficiency, sustainability, and cost savings.

The LGSF technology primarily involves use of galvanised steel which is rust proof, mold resistant and waterproof and the steel offers resistance against any form of corrosion. Moreover, it is environment-friendly. As compared to concrete buildings, buildings with this new technology will offer various environmental benefits such as less energy is required to produce steel against concrete materials, cropping down of CO2 emissions against concrete structures and the ability to recycle the steel used to build the structure at the end of its life cycle.

How does LGSF work?

Light Gauge Steel Framing (LGSF) technology harnesses cold-formed steel sections to establish a robust structural framework for buildings.

Design and Engineering:

The process commences with meticulous design by architects and engineers. Computer-aided design (CAD) software is employed to ensure the structure meets specific requirements and adheres to necessary load-bearing capacities.

Manufacturing and Panelization:

In the manufacturing phase, cold-formed steel sections are produced from galvanized steel coils through processes like roll forming, shaping them into the desired profiles, and cutting them to specified lengths. These steel sections are assembled into panels or frames at the manufacturing facility, pre-engineered and pre-punched for efficient on-site assembly.

Transportation and On-Site Assembly:

Prefabricated panels are transported to the construction site, reducing the need for on-site fabrication and minimizing construction time. On-site, these prefabricated steel panels are efficiently erected and connected, forming the fundamental structural framework of the building.

Foundation and Structural Assembly:

A carefully prepared foundation, in line with the building design, provides a stable base for the steel structure. The prefabricated steel panels are then assembled to create the structural framework.

Component Addition and Finishing:

Following the structural assembly, additional building components such as insulation, sheathing, windows, doors, and interior finishes are added to complete the structure. Exterior and interior finishes are applied to achieve the desired appearance and functionality.

Utilities and Integration:

Plumbing, electrical, and other utility services are seamlessly integrated into the structure as needed, ensuring the building meets both functional and regulatory standards.

Advantages of LGSF

Light Gauge Steel Framing (LGSF) construction offers several advantages:

1. Speed of Construction: LGSF structures can be erected quickly due to the prefabrication of components, reducing construction time compared to traditional methods.

2. Cost-Effective: The efficiency of manufacturing and on-site assembly contributes to cost savings in terms of labor and material expenses.

3. Design Flexibility: LGSF allows for versatile architectural designs and can accommodate various building shapes and sizes, providing flexibility in construction.

4. Strength and Durability: Cold-formed steel sections used in LGSF are durable, resistant to pests, and have a high strength-to-weight ratio, ensuring a robust and long-lasting structure.

5. Reduced Waste: The precision of prefabricated components minimizes on-site waste, making LGSF a more sustainable construction option.

6. Lightweight Construction: LGSF structures are generally lighter than traditional alternatives, reducing the load on foundations and enabling construction on a wider range of soil types.

7. Consistent Quality: Factory-controlled manufacturing ensures consistent quality of steel components, reducing the likelihood of on-site errors and enhancing overall structural integrity.

8. Energy Efficiency: LGSF structures can easily integrate insulation materials, enhancing energy efficiency and meeting modern sustainability standards.

9. Adaptability for Retrofitting: LGSF can be used for retrofitting existing structures, providing a modern and efficient upgrade to older buildings.

10. Fire Resistance: Steel has inherent fire-resistant properties, and LGSF structures can be designed to meet specific fire safety requirements.

11. Minimal Foundation Requirements: The lightweight nature of LGSF construction can lead to reduced foundation requirements, further optimizing cost and construction time.

12. Predictable Construction Schedule: With prefabricated components, construction schedules are more predictable, allowing for better project planning and management.

13. Environmentally Friendly: The reduction in on-site waste, efficient use of materials, and recyclability of steel make LGSF construction environmentally friendly.

These advantages collectively make Light Gauge Steel Framing a popular choice in modern construction, suitable for a variety of applications from residential buildings to commercial structures.

Why the demand for LGSF in India?

In the Indian context, the demand for Light Gauge Steel Framing (LGSF) has surged due to factors such as rapid urbanization, population growth, and the need for quick, affordable, and sustainable construction solutions. LGSF's speed of construction, design flexibility, resource efficiency, and government initiatives promoting affordable housing contribute to its popularity.

Government initiatives in India, such as the "Pradhan Mantri Awas Yojana (PMAY)" and "Smart Cities Mission" play a crucial role in driving the demand for Light Gauge Steel Framing (LGSF). These programs focus on promoting affordable housing, sustainable urban development, and modern construction techniques. By supporting initiatives that align with LGSF's benefits, the government contributes to the adoption of innovative and efficient construction methods in the country.

Additionally, its role in disaster-resilient construction and alignment with the trends of industrialization and modernization make LGSF a compelling choice in the evolving Indian construction landscape.

Applications of LGSF

1. Residential Construction: LGSF is frequently used in the construction of single-family homes, apartments, and other residential structures due to its speed, cost-effectiveness, and design flexibility.

2. Commercial Buildings: LGSF is used in various commercial structures, including office buildings, retail spaces, and warehouses, where its versatility and quick construction time are advantageous.

3. Educational Facilities: Schools and educational institutions often choose LGSF for its ability to accommodate diverse architectural designs and the efficiency of construction, meeting tight project schedules.

4. Healthcare Facilities: Hospitals and healthcare buildings benefit from the strength, durability, and adaptability of LGSF construction, especially when specific design requirements need to be met.

5. Industrial Buildings: LGSF is suitable for constructing industrial facilities such as manufacturing plants and warehouses, where quick assembly and cost-effectiveness are crucial.

6. Hotels and Hospitality: The efficiency of LGSF construction makes it a viable option for hotels and hospitality structures, ensuring timely completion and cost savings.

7. Multi-Storey Structures: LGSF can be used in the construction of multi-story buildings, providing a lightweight yet sturdy alternative to traditional construction methods.

8. Modular Construction: LGSF is well-suited for modular construction, allowing for the efficient prefabrication of components that can be assembled on-site or off-site.

9. Infrastructure and Utilities: LGSF can be applied in the construction of utility buildings, such as power stations or water treatment facilities, due to its durability and ease of assembly.

10. Adaptive Reuse and Retrofitting: LGSF can be employed for adaptive reuse projects or retrofitting existing structures, providing a modern and efficient upgrade to older buildings.

11. Emergency Housing: LGSF is used in the construction of emergency or temporary housing due to its rapid assembly and flexibility in design.

The market potential of LGSF in India

Demand for light gauge steel construction is from both the infrastructure, as well as the real estate sectors. Contractors these days want a combination of economy, strength, and speed. Light gauge steel construction provides all this, apart from enabling the creation of aesthetically pleasing designs too. No wonder steel buildings are in demand nowadays. The steel revolution has started in India. However, the country needs a lot of catching up to do when compared with countries such as China, USA, Canada, Germany, Finland, Turkey, New Zealand, Australia, and Japan. This is one market segment that has the potential for huge growth since what has been tapped is only the tip of the iceberg.In a country like India, where weather varies from one region to another.

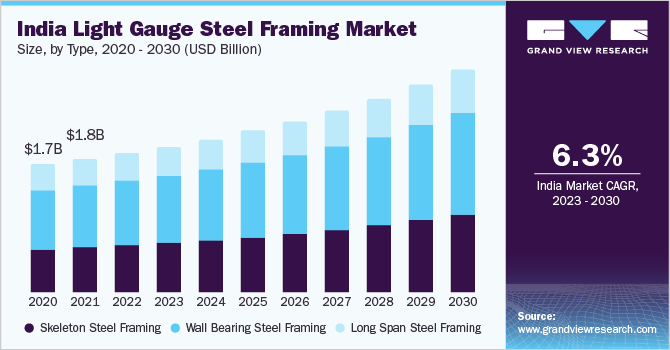

As per grandviewresearch report, the India light gauge steel framing market size was valued at USD 1,887.5 million in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. The major factors attributing to the growth of the market are urbanization accelerating the adoption of modern construction techniques; the rising population leading to the increasing demand for housing. In addition, the aspects such as the increasing demand for green and sustainable buildings is further bolstering the growth of the market. The implementation of government housing schemes on a large scale is expected to positively impact the growth of the target market in the country owing to announcements made by India's central and state governments.

Furthermore, improved insulation techniques for light gauge steel frames have reduced the risk of fire outbreaks in the recent past, improving the structural safety of buildings. Additionally, the use of long-span frames has proven beneficial in industrial building applications owing to the immense stability provided by the light gauge steel structures, which is expected to drive market growth over the forecast years. The Bureau of Indian Standards (BIS) has formulated standards regarding the load, design, and earthquake resistance parameters for building construction materials. Majority of the key players provide target products that conform to not only Indian standards but also international standards such as International Organization for Standardization (ISO).

Market Challenges

The high thermal conductivity of steel is a major factor restraining the industry's growth. The high thermal conductivity largely affects a building's performance during summer, resulting in increased use of air-conditioning equipment and power consumption to maintain comfortable temperatures, thereby impacting sustainability as increased power consumption creates a negative environmental impact. Additionally, the availability of several alternatives to light gauge steel framing, such as traditional/RCC construction, restrains the market growth over the forecast period.

Conclusion

Light Gauge Steel Framing (LGSF) technology is revolutionizing construction in India, offering a faster, more cost-effective, and environmentally friendly alternative. Its ability to swiftly assemble buildings, coupled with design flexibility and cost savings, makes it a standout choice for the evolving construction landscape. As India grapples with rapid urbanization and a demand for affordable housing, LGSF emerges as a superhero, providing a solution that aligns with modern needs while minimizing environmental impact. With government support and a commitment to sustainable practices, LGSF is shaping the future of construction in India, promising efficient, resilient, and adaptable structures for a growing and dynamic society.

Images- Galva Strong, Stratus Steel, Aron Developers, Volta Green Structures

.png)