The adoption of drones in construction has moved beyond aerial photography to advanced diagnostic applications. Thermal imaging drones combine unmanned aerial vehicle (UAV) mobility with infrared sensors, enabling inspection teams to identify temperature variations that indicate structural anomalies, insulation failures, moisture ingress, or electrical system issues. This supports preventive maintenance, quality assurance, and compliance with inspection standards in both new construction and existing assets.

Working Principle of Thermal Imaging in Drones

Thermal imaging works on the principle of detecting infrared radiation emitted by surfaces. All objects above absolute zero emit infrared energy. The amount of radiation varies with temperature, material type, and surface properties. Thermal cameras mounted on drones measure this energy and convert it into a visual map where temperature differences are represented by contrasting colors or grayscale tones.

Key technical elements include:

- Infrared Sensor Array: Captures thermal radiation at wavelengths between 8–14 micrometers.

- Thermal Resolution: Defines the smallest temperature difference detectable, often measured in millikelvins.

- Spatial Resolution: Determined by detector array size and lens quality, affecting image clarity.

- Calibration Systems: Compensate for environmental factors such as ambient temperature, wind, and solar heating.

- When integrated with drones, these sensors can scan large areas quickly and reach locations that are difficult or unsafe for human inspectors.

Applications in Construction

Thermal imaging drones have multiple applications across the construction lifecycle, from early-stage inspection to long-term maintenance. These include:

1. Building Envelope Inspection

- Detection of heat loss or gain through walls, roofs, and glazing.

- Identification of missing or damaged insulation.

- Locating thermal bridges in steel or concrete frames.

2. Moisture and Water Leak Detection

- Pinpointing water ingress in flat roofs, terraces, and podium slabs.

- Identifying dampness behind cladding or in masonry walls.

- Assessing waterproofing performance in basements and retaining walls.

3. Electrical and Mechanical Systems Monitoring

- Identifying overheating in temporary power distribution boards.

- Detecting faults in rooftop solar photovoltaic modules.

- Monitoring temperature variations in HVAC ducting and mechanical plant rooms.

4. Concrete and Structural Assessment

- Detecting uneven curing patterns in fresh concrete.

- Locating subsurface voids or delamination in slabs and panels.

- Assessing heat distribution in structures exposed to fire or thermal stress.

5. Large Infrastructure Asset Management

- Bridge deck thermal scans for identifying moisture intrusion.

- Road and runway inspections for detecting subsurface voids.

- Monitoring of dam structures for seepage detection.

6. Quality Control During Construction

- Verifying insulation installation before interior finishes are applied.

- Confirming waterproofing membrane continuity after application.

- Checking energy efficiency compliance in green building projects.

7. Post-Disaster Damage Assessment

- Evaluating building envelopes for storm-related water penetration.

- Inspecting fire-damaged structures for residual heat and compromised materials.

- Supporting insurance claim documentation with thermal evidence.

Types of Thermal Imaging Drones

Thermal imaging drones vary in design, capability, and operational purpose. Broadly, they can be classified into the following types:

1. Integrated Thermal Camera Drones

These drones have thermal cameras built into their structure by the manufacturer. They offer optimised weight distribution, stable gimbal control, and direct compatibility with drone software. Suitable for users requiring ready-to-deploy systems without additional payload configuration.

2. Payload-Compatible Drones

These UAVs allow the attachment of external thermal imaging payloads. They are preferred by inspection companies that switch between different camera types depending on the project. This type is suitable for applications requiring higher-resolution sensors or dual optical-thermal configurations.

3. Dual-Sensor Drones

Equipped with both RGB (visual) and thermal sensors, these drones allow simultaneous collection of visual and thermal data. This enables precise defect location mapping and comparison between visual cues and thermal anomalies.

4. Fixed-Wing Thermal Imaging Drones

Designed for large-scale surveying, fixed-wing drones cover greater distances in a single flight than multi-rotor models. They are used for inspecting extensive infrastructure such as highways, rail networks, and large industrial facilities.

5. Tethered Thermal Drones

These drones are connected to a ground power source via a cable, enabling extended flight times. Tethered systems are suited for long-duration monitoring of specific structures, such as bridge joints or high-rise façade works.

6. Hybrid VTOL (Vertical Take-Off and Landing) Thermal Drones

Combining vertical take-off with efficient forward flight, hybrid VTOL drones are effective for projects that require both precise hovering and long-distance coverage. This type is applicable in inspecting both compact and spread-out construction sites.

Advantages Over Traditional Methods

- Inspections are conducted without dismantling structural elements.

- Defects in high or hazardous areas can be detected without physical scaffolding or rope access.

- Large façades and roofs can be scanned in short timeframes.

- Identifies potential problems before they progress to visible damage.

- Data can be stored for future maintenance reference and compliance documentation.

Integration with Other Technologies

Thermal imaging drones are increasingly combined with other inspection and analysis tools:

- BIM Integration: Thermal maps are overlaid onto Building Information Models for centralised defect tracking.

- AI Analysis: Automated software identifies thermal patterns and flags areas for human review.

- GIS Mapping: Geo-referenced imagery allows precise location tagging for defect remediation planning.

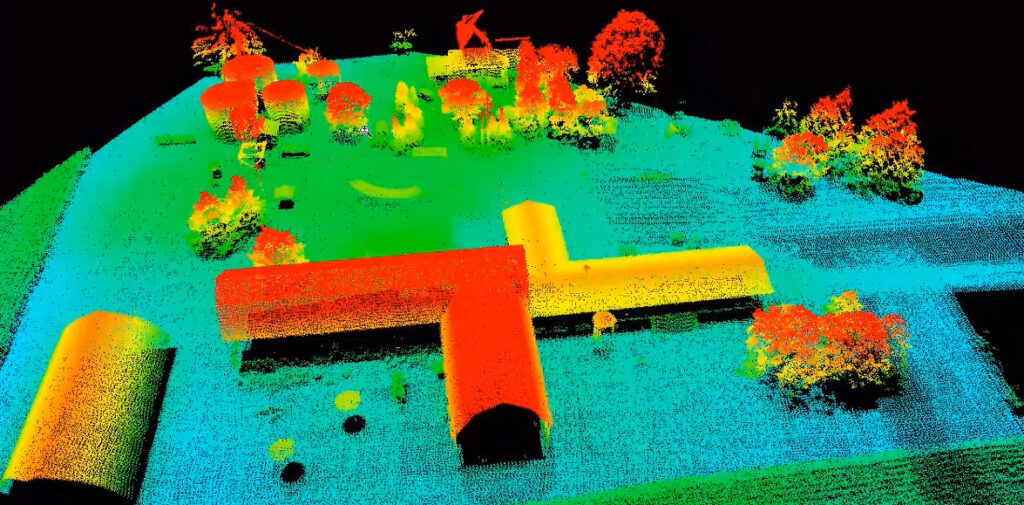

- LiDAR Data Fusion: Combining temperature mapping with 3D models enables detailed spatial and thermal analysis.

Companies Offering Thermal Drone-Based Inspection Services in India

GarudaUAV (Garuda Aerospace)

Offers drone surveying, mapping, and both visual and thermal inspections for a range of sectors, including solar plants, thermal power facilities, factories, dams, telecom towers, and construction sites. They also support construction progress monitoring and asset inspections.

YelloSKYE

Delivers thermal scanning and radiometric thermographic imaging for solar plant inspection, down to string and table-level defect identification. Also provides BIM conversion and digital twin modeling for bridge inspection.

Atom Aviation

Leads in drone surveying and analytics across industries, offering thermal mapping in energy and power sectors, including aviation applications. Applies to infrastructure projects such as construction, railways, mining, and energy.

SES Digital

Offers drone services alongside advanced Industry 4.0 solutions, including 3D laser scanning, AR/VR, AI, and smart motor technologies. Provides drone-based visual and thermal inspections for manufacturing facilities, construction, infrastructure, and industrial assets.

Envoler Innovations

Specializes in drone solutions for thermal inspections, GIS/topographic surveys, solar IV curve assessments, smart city mapping, road and rail surveys, and more.

Trishunya

Provides aerial thermal inspections using UAVs with thermal imaging cameras—suitable for detecting heat loss, moisture intrusion, and electrical faults. Operates in Ahmedabad and Bhavnagar, but offers globally available services.

Digital Edge

Offers drone-based heat mapping for switchyards and solar plants, identifying hotspots in electrical equipment and underperforming solar panels. Services include advanced sensor-based thickness gauging for industrial assets.

Industrial NDT Baroda

Provides drone-aided visual and thermal imaging inspections—ideal for hard-to-reach and hazardous areas like offshore towers, solar farms, wind turbines, storage tanks, and construction sites.

Insight Aviations

Delivers aerial data acquisition across sectors such as construction, infrastructure, solar plants, and thermal power. Their services include inspections, surveillance, construction mapping, and thermal plant monitoring.

Quaddynamics

A startup offering thermography drone services for structural damage assessments. Their drones enable thermal inspection in operational environments, including low-light and low-visibility conditions.

Elion Technologies

Provides drone thermography and aerial inspections for construction, infrastructure, and industrial assets. Services include heat mapping, defect detection, and visual documentation for project monitoring and maintenance.

Operational Considerations

1. Flight Planning

Optimal inspections require:

- Defined flight paths with sufficient image overlap.

- Selection of altitude based on required detail.

- Consideration of site restrictions and safety zones.

2. Environmental Influences

Data accuracy can be affected by:

- Solar Heating: Surfaces heated unevenly during the day may obscure true defects.

- Wind: Alters surface cooling rates, impacting readings.

- Time of Day: Early morning and late evening are often best for detecting moisture or insulation anomalies.

3. Data Processing

Post-capture data processing is necessary to:

- Remove environmental noise.

- Adjust thermal gradients for visibility.

- Annotate and store data in asset management systems.

Regulatory and Safety Compliance

Operating drones for construction defect detection requires compliance with aviation authority regulations in each country. This generally includes:

- Licensed operators.

- Permissions for flights in controlled airspace.

- Risk assessments for flights over occupied zones.

Thermal inspections must also align with relevant building codes and privacy laws when surveying occupied premises.

Future Outlook

Thermal imaging drones are poised for significant technological advancements in the coming years. Future developments are expected to include higher resolution sensors with enhanced temperature sensitivity, allowing for the detection of smaller and more subtle thermal variations. Artificial intelligence will play a greater role in automating defect classification, reducing the time and human effort required for data interpretation. Integration with cloud-based platforms will enable real-time monitoring and collaborative decision-making across project teams, improving response times for maintenance and repairs. Additionally, these drones are likely to be combined with other non-destructive testing (NDT) methods, creating a more comprehensive and multi-layered inspection approach that enhances accuracy and operational efficiency across construction, infrastructure, and industrial applications.

Conclusion

The strategic importance of thermal imaging drones in construction lies not only in their inspection efficiency but also in their ability to feed actionable data into broader decision-making frameworks. By enabling precise defect localization and quantifiable thermal performance metrics, they allow contractors, asset owners, and facility managers to shift from reactive repairs to predictive maintenance models. This transition can significantly reduce lifecycle costs, extend asset longevity, and improve energy efficiency benchmarks, making thermal inspection a contributor to both economic and environmental performance goals. For large-scale infrastructure, where failures can have public safety and financial consequences, the ability to detect anomalies at an early stage offers a measurable risk mitigation advantage.

Images- elion.co.in, sesdigitalsolutions.com