The construction industry is undergoing a significant transformation, driven by the rise of advanced digital tools. Among these, digital twins are emerging as a revolutionary technology, fundamentally altering how projects are designed, managed, and maintained. These virtual replicas offer a dynamic, real-time view of construction assets, enabling teams to make informed decisions and optimize performance. But what exactly are digital twins, and how are they applied in construction?

What Is a Digital Twin?

A digital twin refers to an exact virtual replica of a building, bridge, highway, or even an entire city. These models go beyond traditional Building Information Modeling (BIM) by integrating real-time data and analytics, enabling continuous updates that reflect the current state of the physical asset. In essence, they become a "living" model that evolves along with the construction or operational process.

How Are Digital Twins Created?

The creation of a digital twin involves gathering extensive data from the real world. Technologies like 3D laser scanning, drones, cameras, and Internet of Things (IoT) sensors play a crucial role in capturing this information. These devices collect physical data—such as dimensions, position, and movement—and send it to a centralized system. When combined with artificial intelligence (AI) and cloud computing, digital twins can process and analyze massive volumes of data, allowing for real-time updates and insights.

For example, digital twins can monitor stress loads on bridges caused by traffic or wind, detect leaks in pipes, or measure the impact of environmental changes on buildings. The ability to simulate such conditions before they occur in the physical world provides a valuable tool for predicting and preventing potential issues.

Accessing and Maintaining Digital Twins

To ensure seamless access to digital twins, specialized software platforms like Trimble Connect, Quadri, Agile Assets, and Tekla are used. These platforms provide a centralized hub where stakeholders can view, share, and manage digital twin data. Because construction projects involve multiple teams working in different locations, having a "single source of truth" is essential for collaboration and decision-making.

One of the core strengths of digital twins is their ability to remain in sync with the physical asset throughout the construction lifecycle. This is made possible through BIM software, IoT sensors, and 3D modeling tools, which continuously feed data back into the model. Scanning technologies, such as point cloud data, also help keep the digital twin current by comparing the actual built environment with the original design. The result is a dynamic, real-time model that evolves alongside the physical project.

Enhancing BIM Capabilities

Building Information Modeling (BIM) has become an indispensable tool in modern construction, allowing teams to create detailed, 3D models of structures before they are built. However, the integration of digital twins takes BIM to the next level. By collecting real-time data and automatically updating the model, digital twins enhance the analytical capabilities of BIM, providing a more comprehensive view of how a building or infrastructure asset behaves in the real world.

For instance, digital twins enable stakeholders to visualize the working conditions, positioning, and status of every physical component in the structure. Whether it’s monitoring a bridge’s stress points or tracking the efficiency of energy systems in a skyscraper, digital twins give construction teams the insights they need to optimize performance and ensure long-term sustainability.

Key Benefits of Digital Twins in Construction

Digital twins offer a wide array of benefits throughout the entire construction lifecycle, from planning and design to operations and maintenance. These advantages include:

1. Improved Resource Management: With real-time data being sent from the field to the office, digital twins create an information pipeline that allows teams to anticipate resource allocation issues and balance labor costs with budgets. This enhances job site efficiency, reducing waste and improving project timelines.

2. Enhanced Connectivity: Digital twins centralize information in one platform, allowing for better collaboration among project stakeholders. Automatic updates to 3D models with data from sensors and IoT devices ensure that no detail is lost over time. This is particularly valuable for complex projects that require the integration of various systems and teams.

3. Ongoing Value for Facility Management: Digital twins continue to deliver value even after construction is complete. Facility managers can use the virtual model to monitor and manage the building’s performance, identifying areas that require repairs or upgrades. The model can also streamline operations by providing detailed specifications for technicians, reducing downtime and maintenance costs.

4. Informed Decision-Making: The predictive capabilities of digital twins allow project teams to experiment with changes in a virtual environment before implementing them in the real world. This reduces the risk of costly mistakes and helps inform future decisions, particularly when it comes to renovations or structural enhancements.

India’s Growing Need for Digital Twin Technology

India is undergoing a massive infrastructure overhaul, with key government initiatives like the Smart Cities Mission, Bharatmala Pariyojana, and the Atal Mission for Rejuvenation and Urban Transformation (AMRUT). These programs aim to develop sustainable urban environments with efficient transportation, smart energy management, and enhanced public services. The sheer scale of these projects necessitates advanced technologies like digital twins to manage complexity, streamline workflows, and ensure resource optimization.

In addition, the National Infrastructure Pipeline (NIP), which outlines ₹111 lakh crore worth of infrastructure projects, requires high levels of accuracy in planning, execution, and monitoring. Digital twin technology can contribute significantly to these efforts by improving real-time collaboration, reducing errors, and delivering infrastructure projects within budget and timelines.

Applications of Digital Twins in India’s Construction Industry

1. Smart Cities Development

India’s Smart Cities Mission aims to create urban spaces that use technology to improve the quality of life for residents. Digital twins are pivotal in this transformation, enabling city planners to simulate various scenarios and optimize urban design. For instance, cities like Pune and Ahmedabad are integrating smart technologies for traffic management, waste disposal, and energy efficiency, and digital twins allow for real-time monitoring and predictive maintenance of infrastructure.

Digital twins can simulate the impact of new developments, such as residential buildings, commercial centers, and public infrastructure, on traffic congestion, water supply, and energy demand. This holistic view helps urban planners make informed decisions, ensuring that the cities of the future are not only smart but also sustainable.

2. Enhancing Project Management and Efficiency

Construction projects in India often face issues like time and cost overruns due to delays, miscommunication, and unforeseen challenges. Digital twin technology provides a real-time, centralized source of truth for project stakeholders, ensuring that everyone is aligned on the project’s progress. This is particularly important in large infrastructure projects such as highways, railways, and metro systems, where multiple contractors and teams need to collaborate efficiently.

With digital twins, construction teams can simulate potential issues before they arise, optimizing resource allocation, and identifying the most efficient ways to execute tasks. This capability is especially useful in India’s complex and dense urban environments, where construction can disrupt daily life.

3. Optimized Maintenance and Operations

Digital twins are not just useful during the construction phase but continue to provide value throughout the operational lifecycle of the asset. Once a building, bridge, or railway line is operational, digital twins can help facility managers monitor performance, predict maintenance needs, and identify potential failures before they occur.

For example, in India's sprawling urban infrastructure, where maintenance is often neglected, digital twins can help monitor critical aspects like structural health, energy consumption, and water leakage. By continuously gathering data from IoT sensors embedded in the asset, the twin can alert operators to issues like cracks in a bridge or excess strain on a building’s foundation, helping prevent accidents and extending the asset’s lifespan.

4. Environmental and Resource Management

Digital twins are playing a significant role in environmental sustainability in construction projects in India. By simulating different construction materials, energy systems, and building designs, digital twins can help assess the environmental impact of a project before it is built.

In a country like India, where sustainability and efficient resource management are key to urban development, digital twins can ensure optimal use of materials, reduce carbon footprints, and help design energy-efficient buildings. Moreover, cities like Bengaluru, which are facing severe water shortages, can use digital twins to monitor water usage and optimize distribution systems to avoid wastage.

Market Potential of Digital Twins

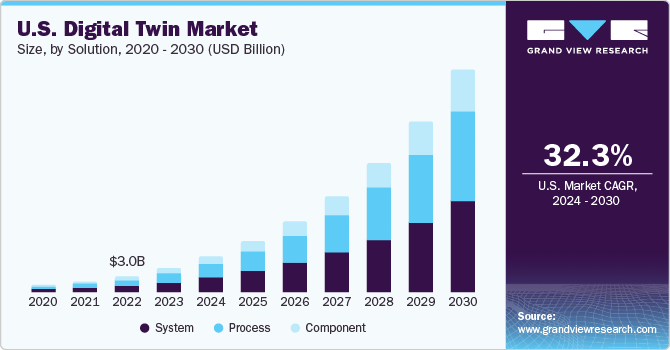

As per Grandview Research Report, The global digital twin market size was estimated at USD 16.75 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 35.7% from 2024 to 2030. Digital twin technology is gaining traction owing to its potential to bridge the gap between the physical and virtual worlds. The global market is expected to grow significantly over the forecast period in line with the growing adoption of the Internet of Things (IoT) and big data analytics and the growing need to ensure cost-efficient operations, optimized processes, and reduced time to market.

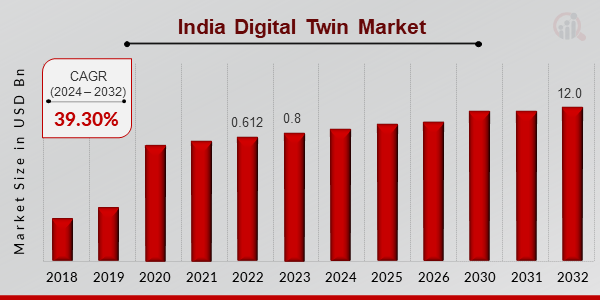

The future of digital twins in India looks promising as more government and private sector initiatives adopt the technology. As per Market Research Future Report, India Digital Twin Market Size was valued at USD 0.612 Billion in 2022. The Digital Twin Market industry is projected to grow from USD 0.8 Billion in 2023 to USD 12.0 Billion by 2032, exhibiting a compound annual growth rate (CAGR) of 39.30% during the forecast period (2024 - 2032). Technological advancements and increased demand for predictive maintenance are the main market drivers anticipated to propel the Digital Twin Market in India.

Indian cities like Hyderabad, Pune, and Kochi are already exploring the use of digital twins to enhance urban planning and improve public services. Moreover, companies like Tata Consultancy Services (TCS) and Larsen & Toubro (L&T) are developing advanced digital twin solutions for their infrastructure and construction projects, further accelerating the adoption of this technology.

As India continues to build its urban future, digital twins will become an essential tool for ensuring that construction projects are efficient, cost-effective, and sustainable. By bridging the gap between the physical and digital worlds, digital twins are set to revolutionize how India constructs and manages its infrastructure.

Overcoming Challenges in Adopting Digital Twins in India

Despite the immense potential of digital twins, their adoption in construction sector is not without challenges. The primary hurdle is the lack of digital infrastructure and expertise required to implement this technology on a large scale. Many construction companies in India still rely on outdated practices, and the shift to digital twin technology requires substantial investment in training and equipment.

Another challenge is the issue of data management. Digital twins generate vast amounts of data, and managing this data securely and efficiently is critical to the success of the system. With the rise in cyber-attacks, ensuring data protection for large-scale infrastructure projects becomes paramount.

Finally, there is the challenge of integrating digital twins with existing systems and workflows. Construction firms need to embrace a more collaborative approach, integrating digital twins with BIM and IoT systems to reap the full benefits of the technology.

Conclusion

Digital twins are poised to revolutionize the construction industry, providing a powerful tool for real-time data analysis, project optimization, and asset management. By bridging the gap between the physical and digital worlds, they enhance BIM capabilities and offer valuable insights at every stage of a project’s lifecycle. As technology continues to evolve, digital twins will play an even more prominent role in the future of construction, enabling smarter, more efficient processes that improve outcomes and reduce costs.

Image sources- bitsathy.ac.in,bdcnetwork.com

.png)