In a development that could significantly shift how infrastructure interacts with energy systems, a research team led by Professor Zhou Yang from Southeast University, China, has engineered a new type of cement-based material capable of generating and storing electricity. This breakthrough, recently published in Science Bulletin, represents a significant advancement in the field of thermoelectric materials, particularly within the domain of construction.

Overcoming Cement’s Traditional Limitations

Cement, the foundation of most modern infrastructure, has long been known to possess certain ionic thermoelectric properties. However, in its conventional form, these properties have remained largely underutilized due to the dense and static nature of cement’s internal matrix. The challenge has always been the restricted mobility of ions, which is necessary for any meaningful thermoelectric conversion.

The ionic thermoelectric effect—where temperature differences drive the movement of ions and generate electric potential—has been observed in cement. But without a mechanism to boost ion mobility and create a substantial difference in diffusion rates between cations and anions, the practical application of this phenomenon remained limited.

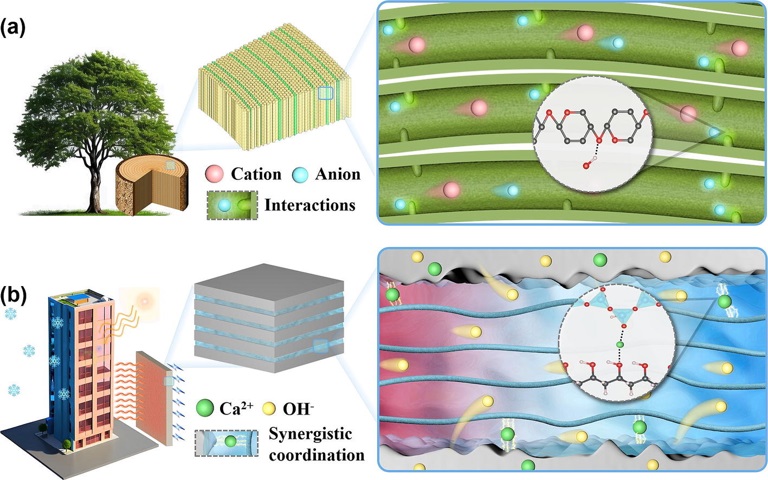

Addressing this issue head-on, the research team employed a biomimetic design approach. They drew inspiration from the internal layered structure found in plant stems to create a composite material that alternates between cement layers and polyvinyl alcohol (PVA) hydrogel layers. This multilayered architecture facilitates faster ion transport and enhances the Seebeck coefficient, a measure of thermoelectric efficiency.

Image source- msn.com

Key Performance Metrics and Material Innovation

The resulting cement-hydrogel composite demonstrated a Seebeck coefficient of −40.5 millivolts per Kelvin (mV/K), which is nearly ten times higher than previously recorded values for cement-based thermoelectric materials. Furthermore, the material achieved a figure of merit (ZT) of 6.6×10⁻²—six times greater than earlier cement materials.

These gains are the direct result of a deliberate structural strategy. Hydrogel layers within the composite provide a medium where hydroxide ions (OH⁻) can move quickly, while calcium ions (Ca²⁺) are more strongly immobilized at the cement-hydrogel interface. This differential ion mobility increases the electric potential generated when the material is exposed to a temperature gradient.

The multilayer system also maximizes the number of interfaces within the material. Each interface becomes a zone for selective ion interaction, which contributes to higher overall performance. Such a system not only enhances electricity generation but also introduces energy storage capabilities due to the electric double layer formation between the cement and hydrogel interfaces.

Integration with Smart Infrastructure

One of the most compelling aspects of this development lies in its potential applications. With urban infrastructure increasingly incorporating sensors, communication systems, and automation, the demand for decentralized and self-sustaining energy sources has grown.

This cement-hydrogel composite serves as both a structural and an energy-converting material. Buildings, bridges, pavements, and even roadside barriers could theoretically generate electricity from ambient heat differences—be it between interior and exterior surfaces or day and night temperature fluctuations.

Power generated from this material could support embedded sensors used for structural health monitoring, temperature regulation, or environmental data collection. The ability to locally power such devices without reliance on external grids or frequent battery replacement would significantly reduce maintenance costs and enable the development of more autonomous, long-lasting infrastructure.

Implications for the Construction Industry

This innovation comes at a time when the construction industry is facing intense pressure to reduce carbon emissions and improve resource efficiency. Cement production alone accounts for roughly 8% of global carbon emissions. While this new material does not directly address the carbon intensity of cement, it does shift the value proposition of concrete from being a passive element to an active component of energy ecosystems.

Moreover, the use of bio-inspired designs in such a high-volume material suggests new directions for sustainable engineering. The hydrogel used is based on polyvinyl alcohol, a widely available and relatively stable polymer, and the fabrication method does not require high-temperature processing or rare elements—factors that could support scalability and cost-effectiveness in the long term.

At the upcoming SynBioBeta conference, a session titled “Conquering Carbon Emissions From the Concrete Industry” is expected to further explore how synthetic biology and material science are converging to address environmental challenges. Innovations like this cement-hydrogel composite are likely to feature prominently in such discussions.

While the current study demonstrates promising performance metrics under controlled conditions, large-scale deployment will require additional research into durability, manufacturability, and long-term performance under real-world stresses. Key questions include how the material behaves under mechanical loads, how well it withstands environmental exposure, and how it integrates with existing construction methods.

Still, the work of Professor Zhou Yang’s team provides a clear proof-of-concept for ionic thermoelectric cement that could transform the way buildings and cities manage power. If adopted widely, the cement could pave the way for infrastructure that is not only strong and functional but also capable of contributing to the power needs of smart, connected environments.

.png)