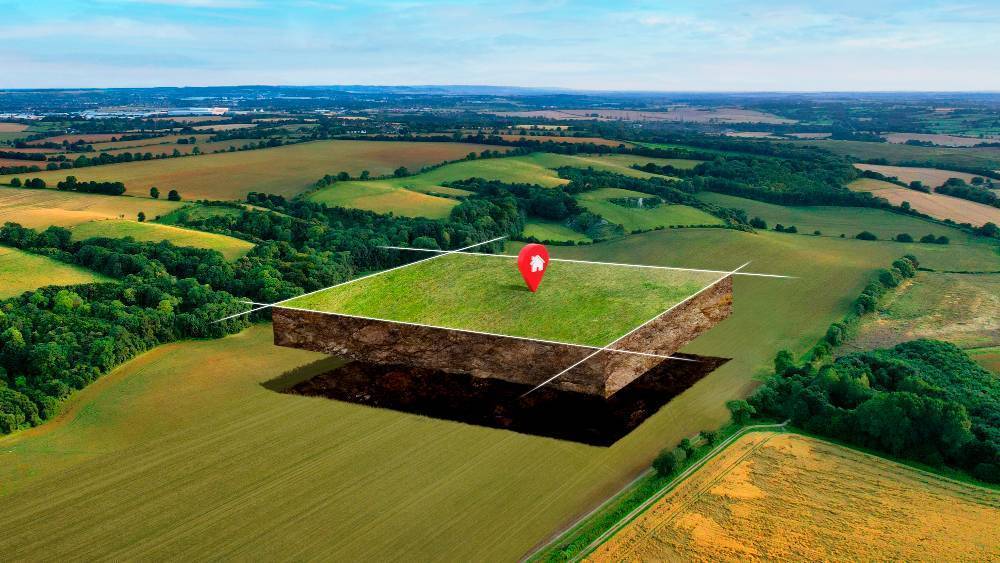

Waterproofing is a crucial part of construction, but it often goes unnoticed—until something goes wrong. When water gets into concrete or masonry, it can cause serious damage like cracks, rust, and weakening of the structure, which can shorten its lifespan. Traditionally, waterproofing meant adding layers like membranes or coatings on the surface. But now, thanks to advances in science, new waterproofing admixtures can be mixed directly into concrete to help stop water from getting in. The big question is: do these modern admixtures really protect buildings over the long term? Are they a real solution, or just marketing claims?

What is Admixture?

Admixture is a chemical additive mixed into concrete or mortar during the production process to enhance its properties, especially waterproofing. It works by altering the internal structure of the material, reducing the size and number of pores and sealing tiny capillaries through which water can penetrate. This internal modification prevents water from passing through the concrete, protecting the structure from moisture-related damage such as cracking, corrosion of embedded steel, and deterioration over time. By providing waterproofing from within, admixtures increase the durability and lifespan of concrete without relying solely on external coatings or membranes.

Types of Next-Generation Waterproofing Admixtures

1. Crystalline Waterproofing Admixtures

Crystalline waterproofing admixtures are one of the most fascinating advancements in concrete technology. These compounds work from within the concrete, activating only when water seeps in. When moisture enters, the admixture reacts chemically with cement by-products to form tiny, insoluble crystals that grow and fill the micro-pores and hairline cracks inside the concrete matrix. This process effectively blocks the pathways water uses to penetrate, making the concrete itself resistant to water ingress. What makes crystalline admixtures particularly interesting is their ongoing ability to self-seal minor cracks over time, as the crystals continue to grow whenever moisture is present. This means that, unlike traditional waterproofing membranes that can be damaged or wear away, crystalline admixtures create a durable, long-lasting internal barrier that repairs itself to some extent. However, their performance relies heavily on proper curing and concrete quality, and they cannot seal very large cracks on their own.

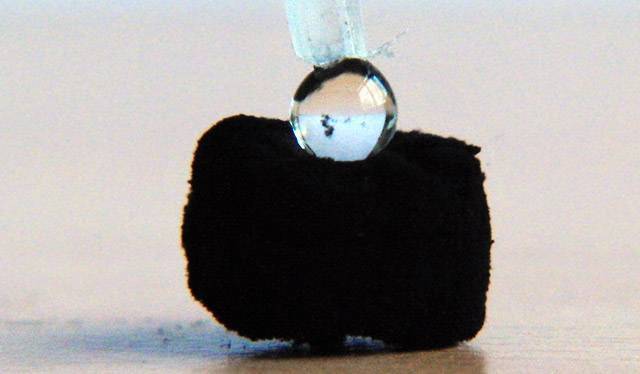

2. Hydrophobic (Water-Repellent) Admixtures

Hydrophobic admixtures operate on a different principle—rather than filling pores or growing crystals, they coat the internal pore surfaces of concrete with water-repelling chemicals. Typically based on silane, siloxane, or other organosilicon compounds, these admixtures chemically modify the pore walls to make them repel water. This means that water trying to penetrate the concrete simply beads up and is discouraged from entering the pores, similar to how water rolls off a waxed car surface. One of the key benefits of hydrophobic admixtures is that they allow the concrete to “breathe,” meaning water vapor can still escape, which helps prevent moisture buildup and potential damage from trapped vapor. While very effective at reducing water absorption and capillary action, hydrophobic admixtures tend to have limitations in situations with constant water pressure and may gradually lose effectiveness as the hydrophobic agents can degrade or leach out over time.

3. Pore-Blocking and Densifying Admixtures

Pore-blocking admixtures focus on physically reducing the volume and connectivity of pores inside concrete. These products often use polymer or silica-based chemicals that fill or partially clog the tiny channels through which water travels. By making the concrete denser and less porous, these admixtures slow down or prevent water infiltration. Besides improving waterproofing, they can also enhance the overall strength and durability of concrete by creating a more compact microstructure. Many pore-blocking admixtures also help reduce shrinkage and improve workability of fresh concrete. While these admixtures are effective at reducing permeability, they rarely eliminate it completely. Microscopic pores and vapor pathways usually remain, so while they contribute significantly to waterproofing, they often work best combined with other types of admixtures or treatments.

4. Nanotechnology-Based Admixtures

Nanotechnology is increasingly being harnessed in concrete waterproofing through the inclusion of nanoparticles such as nano-silica, nano-titania, or nano-clay in admixture formulations. These nanoparticles are incredibly tiny—thousands of times smaller than a grain of sand—and their high surface area allows them to interact very effectively with the cement hydration process. When added to concrete, nanoparticles fill the smallest pores and refine the microstructure, dramatically reducing permeability. Some nanoparticles also act as catalysts, accelerating cement hydration and improving the strength and density of the final concrete. Beyond waterproofing, nanomaterials can impart additional functionalities, like self-cleaning surfaces or antimicrobial properties. However, these admixtures can be expensive and require precise control in mixing and dosing to avoid particle clumping, which could reduce effectiveness. While promising, the long-term durability of nano-based waterproofing admixtures is still under study.

5. Hybrid Waterproofing Admixtures

Hybrid waterproofing admixtures combine two or more waterproofing technologies into a single product to harness their complementary strengths. For example, some hybrids merge crystalline growth agents with hydrophobic compounds to both block pores and repel water chemically. Others mix polymer-based pore blockers with nanomaterials to improve density and surface chemistry simultaneously. The goal of hybrid admixtures is to create a more comprehensive and resilient waterproofing system that can protect concrete against a wider range of water ingress challenges, including moisture, pressure, and minor cracking. By combining mechanisms, hybrids often deliver better performance than any single technology alone, offering multi-functional benefits such as self-healing, enhanced durability, and improved chemical resistance. The complexity of their chemistry means careful formulation and quality control are crucial, and these admixtures can be more costly. But for critical infrastructure or high-performance concrete, hybrids can provide an effective, long-term waterproofing solution.

Are Modern Admixtures Delivering Long-Term Protection?

Advantages

- Deeper penetration: Unlike surface treatments, admixtures are distributed throughout the concrete, providing waterproofing from the inside out. This makes the protection less vulnerable to mechanical damage or surface wear.

- Durability: Many crystalline and hydrophobic admixtures produce chemically stable compounds that do not degrade easily over time. The waterproofing effect can theoretically last as long as the concrete itself.

- Self-healing: The ability of crystalline admixtures to grow crystals in moist environments means minor cracks can be sealed without external repair.

- Reduced maintenance: Structures using integral waterproofing tend to require less frequent repairs and have longer service lives.

- Environmental benefits: Integral admixtures often reduce reliance on membranes and coatings, which can contain harmful VOCs or plastics.

Limitations

- Proper application is critical: Dosage, mixing, curing, and environmental conditions can make or break the performance of admixtures. Poor practices reduce effectiveness dramatically.

- Limitations Remain: While admixtures significantly enhance water resistance, they cannot fully prevent leakage caused by large cracks, major construction defects, or structural movements.

- Cost considerations: Next-gen admixtures tend to be more expensive than traditional additives or surface membranes, which can deter adoption on cost-sensitive projects.

- Variability among products: Different manufacturers use different chemistries, so product performance can vary widely. Independent testing and certification are important.

How to Choose the Right Waterproofing Admixture?

When selecting a waterproofing admixture for a project, consider:

- Type of exposure: Is the structure exposed to water under pressure (like below-grade), just rain, or moisture vapor? Different admixtures perform differently under varying conditions.

- Concrete mix design: Compatibility with cement type, aggregates, other admixtures, and mix water content matters.

- Project requirements: Does the project need self-healing? High chemical resistance? Freeze-thaw protection?

- Cost vs. benefit: Sometimes a slightly more expensive admixture can save money in the long term by reducing repairs.

- Manufacturer reputation and certification: Choose products with proven track records and verified test data.

Leading Next-Generation Waterproofing Manufacturers in India

- Pidilite Industries Ltd. (Fevicol, Dr. Fixit)

- Asian Paints (SmartCare Waterproofing Solutions)

- CICO Technologies Ltd.

- BASF India Ltd. (Construction Chemicals Division)

- Fosroc Chemicals (India) Pvt. Ltd.

- Sika India Pvt. Ltd.

- STP Limited (Specialty Chemicals)

- Choksey Chemicals Pvt. Ltd.

- Kryton International Inc.

- Polyglass India

Conclusion

Next-generation waterproofing admixtures represent a major leap forward in protecting concrete structures from water damage. By working from within the material—through crystalline growth, hydrophobic treatment, nanoparticle refinement, or hybrid technologies—these admixtures offer enhanced durability, self-healing capabilities, and reduced maintenance needs compared to traditional surface coatings. When properly applied and combined with quality construction practices, they help extend the lifespan of buildings and infrastructure.

However, these admixtures are not a cure-all; they cannot fully compensate for major cracks or structural defects. Selecting the right product based on project requirements, environmental exposure, and compatibility is essential for optimal performance. For builders and engineers focused on long-term resilience and sustainability, integrating modern waterproofing admixtures into concrete mix designs is a strategic choice that can deliver lasting protection and cost savings over time.

Images- mdpi.com, sidleychem.com, highperformancecoatings.org

.png)