Key Highlights: Steel Recycling in Construction & Infrastructure

- Steel can be recycled repeatedly without loss of mechanical properties, making it suitable for circular use in construction.

- Construction, demolition, and renovation activities generate significant quantities of recyclable steel scrap.

- Recycled steel is used to manufacture reinforcement bars, structural sections, plates, and other construction components.

- India’s domestic ferrous scrap generation has increased, but supply continues to remain below demand for construction steel.

- Government policies and recycling infrastructure development affect scrap collection, processing, and availability for construction and infrastructure sectors.

For a very long time, steel has been the main material that modern construction and infrastructure rely on. Steel is the primary element that makes possible the size, strength, and durability of the built environment in high, rise buildings, industrial complexes, bridges, highways, railway networks, and underground utilities. Steel's contribution to the development of cities and the fulfillment of infrastructure needs has never been so indispensable.

Besides its excellent load- bearing capabilities, what really differentiates steel from other materials is that it can be recycled over and over without losing its original strength and durability and, therefore, it is one of the most environmentally friendly materials on earth for the construction and infrastructure industries.

In a world where doing the right thing for the environment, cutting down on carbon footprints, and saving as much energy and raw materials as possible have become the major focus of any project, recycling steel has turned into one of the main components of sustainable development.

Types of Steel Scrap from Construction and Infrastructure

There are several types of recyclable steel that are generated from construction and infrastructure projects:

Fabrication and Site Scrap- Off, cuts from rebar, waste from fabrication, and changes in construction are all contributions that are very clean and thus can be easily recycled. This type of material is usually collected at the work site and then returned to the steel mills.

Demolition and Decommissioning Scrap- During the demolition of a building, dismantling a bridge or other infrastructure, a large amount of steel scrap is generated. A lot of the steel scrap such as structural beams, columns, and reinforcement steel that is recovered during demolition is recycled.

Renovation and Retrofitting Scrap- When old buildings are upgraded or retrofitted for seismic strengthening, the recoverable steel components that are recycled into new construction materials are produced. These three sources together are the continuous supply of steel scrap that goes into the construction material cycle.

Steel Manufacturing and Recycling for Construction Use

Construction steel in the past was made with blast furnaces and basic oxygen furnaces using mainly iron ore and coal. Although this method was effective, it is an energy, intensive way and carbon, heavy. But methods have changed now and various methoda are available.

Electric Arc Furnace (EAF) Steelmaking

Currently, a large portion of construction steel is made through the use of electric arc furnaces, which mainly use recycled steel scrap. The steps taken in this process are:

- Scrap steel is introduced into the furnace

- Electric arcs melt the material at very high temperaturesImpurities are removed, and the chemical composition is adjusted

- Steel in liquid form is transformed into billets, blooms, or slabsSteelmaking by EAF uses considerably less energy and emits much lower emissions than the traditional ones.

Rolling and Shaping for Construction

Steel after being cast is rolled and shaped into construction products like:

- Reinforcement bars

- Structural beams and channels

- Steel plates and sheets

- Pipes and hollow sections

Final treatments give assurance that the products meet the construction codes and standards for strength, ductility, and durability.

Environmental Benefits of Steel Recycling in Construction Reduced Carbon Footprint

Compared to steel that is made from raw materials, recycled steel only requires a fraction of the energy, which is why it leads to a drastic reduction of greenhouse gas emissions. In large, this helps to achieve the low, carbon construction goals as well as the national climate commitments.

Conservation of Natural Resources

By recycling steel, there is less need for mining iron ore and coal which in turn preserves not only the landscapes but also drastically reduces the consumption of water and energy that is required for the extraction process.

Waste Reduction and Landfill Diversion

Among the various types of waste, construction and demolition waste are two of the largest ones. When steel is recycled, landfill volumes are greatly reduced and at the same time, material management is done in an environmentally responsible manner.

Economic and Project Advantages

Steel recycling brings about real economic benefits for construction and infrastructure projects:

- Lower material costs due to reduced raw material dependence

- Stable supply of steel through domestic recycling networks

- Revenue generation from scrap recovery on construction sites

- Reduced transportation and disposal costs

These benefits have put recycled steel in a double position where, on the one hand, it is sustainable and on the other hand, it is financially attractive for developers, contractors, and governments.

Steel Recycling and Sustainable Infrastructure Development

Modern infrastructure planning is heavily leaning towards the characteristics of durability, flexibility, and environmental friendliness. And steel is the material that can deliver all three.

- Recycled steel is a major factor in these:

- Green building certifications

- Sustainable urban development

- Long, life, low, maintenance infrastructure

- Climate, resilient construction

Steel is a good fit with circular construction principles since it can be taken back at the end of a structure's life and reused endlessly.

Construction Steel Recycling Innovations

Technological progress is helping to figure out ways to recover and reuse steel more than ever on the construction sites:

- Demolition methods that yield maximum steel recovery

- On, site scrap segregation and processingHigh, precision sorting at recycling centers

- Enhanced EAF technologies for the production of construction, grade steel with lower emissions

All these inventions are making sure that steel continues to be one of the most sustainable materials in the built environment.

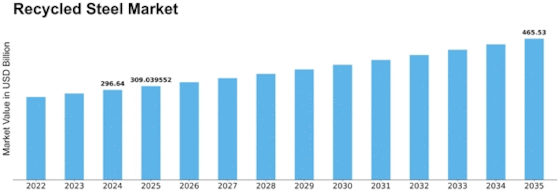

Global Market Potential of Construction Steel Recycling

As per Market Research Future analysis, the Recycled Steel Market Size was estimated at 296.64 USD Billion in 2024. The Recycled Steel industry is projected to grow from 309.04 USD Billion in 2025 to 465.53 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 4.18% during the forecast period 2025 - 2035.

Key Market Trends & Highlights

- The Recycled Steel Market is poised for growth driven by sustainability and technological advancements.

- North America remains the largest market for recycled steel, reflecting robust demand across various sectors.

- Asia-Pacific is emerging as the fastest-growing region, propelled by increasing urbanization and industrialization.

- The ferrous segment dominates the market, while the non-ferrous segment is witnessing rapid growth due to evolving recycling technologies.

Key drivers include the rising demand for sustainable materials and regulatory support for recycling initiatives, particularly in construction and automotive sectors.

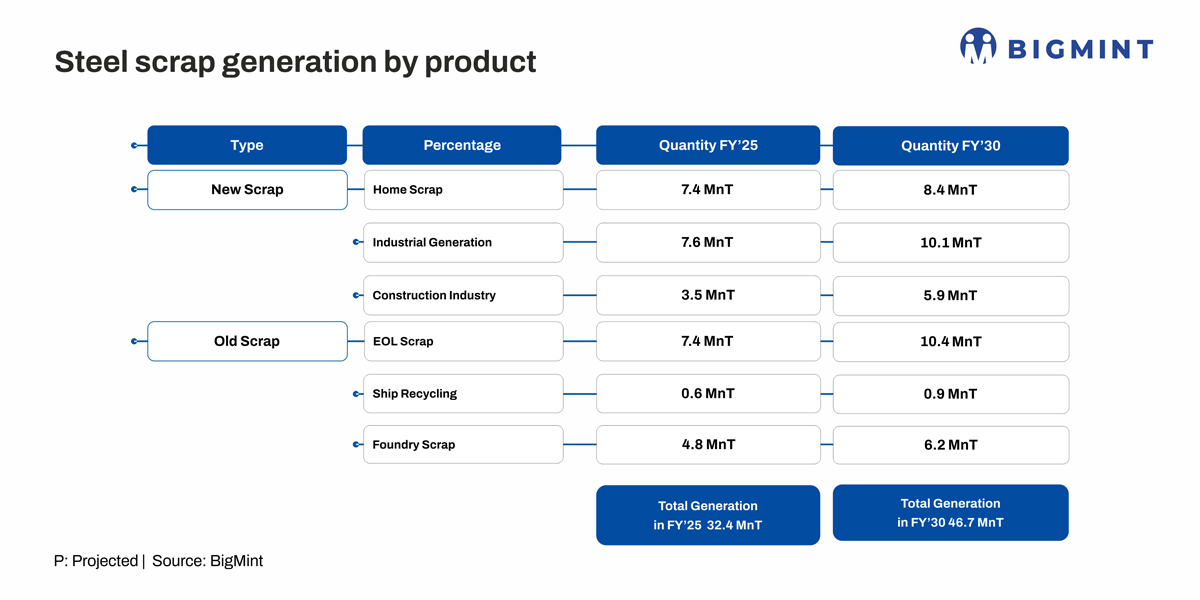

Steel Scrap Generation & Recycling: Implications for Construction

As per BigMint Analysis, Domestic ferrous scrap generation in India increased by 7% year-on-year to over 32 million tonnes (mnt) in FY’25, up from 30 mnt in FY’24. Strengthening scrap availability through upgraded recycling infrastructure and improved end-of-life vehicle (ELV) processing remains a key pillar of government policy, particularly for downstream sectors such as construction-grade steel.

Despite this growth, domestic scrap supply continues to lag demand, reinforcing India’s reliance on imports. According to BigMint estimates, domestic scrap generation is projected to reach 46.7 mnt by FY’30, underlining scrap’s growing strategic importance as a low-carbon input for construction steel such as rebar, structural sections, and fabricated steel components. Policy efforts are increasingly focused on building an organised, efficient scrap value chain to support sustainable construction practices.

The Vehicle Scrappage Policy (2021) is expected to improve scrap availability in the medium term by targeting vehicles with shorter lifecycles, effectively unlocking “low-hanging fruit” for rapid domestic scrap generation. This is particularly relevant for EAF- and IF-based steelmakers, which supply a significant share of construction steel.

Under the Ministry of Steel’s Vision 2047 roadmap, India aims to raise scrap usage in steelmaking to 30% by FY’30, from around 20% currently. This shift will directly support the construction sector’s transition toward lower-carbon steel, aligning with green building norms and infrastructure sustainability goals.

Challenges in Scrap Utilisation for Construction Steel

- Infrastructure gaps: Limited modern shredding and recycling facilities result in inefficient scrap recovery and inconsistent quality.

- Transparency issues: Absence of a centralised pricing and grading framework reduces market confidence for construction-grade scrap.

- Operational inefficiencies: Predominantly manual dismantling increases costs, lowers recovery rates, and raises environmental risks.

As the world’s third-largest automobile manufacturer, India produces ~30 million vehicles annually and has 327 million registered vehicles, creating a vast future scrap pool. However, translating this into reliable, high-quality input for construction steel requires coordinated upgrades across infrastructure, regulation, and operations.

Scrap Potential & Construction Demand Outlook

India’s ferrous scrap consumption is projected to increase from 41.9 mnt in FY’25 to 61.8 mnt by FY’30, driven largely by demand from construction-led steelmaking.

- BOF, EAF, and IF routes: Scrap usage expected to rise from 35.2 mnt to 54.2 mnt, supporting rebar and structural steel output.

- Foundries: Scrap consumption projected to increase modestly from 6.7 mnt to 7.6 mnt, mainly for cast components used in construction and infrastructure.

Even with rising domestic generation, a 6–7 mnt supply gap is likely to persist, sustaining import dependence. Closing this gap through improved scrap collection, processing, and recovery will be critical for ensuring cost-effective, low-emission steel supply for India’s construction and infrastructure growth.

Building the Future with Recycled Steel

Steel has been the backbone of the world\'s skylines and infrastructure, and recycled steel will be at the heart of construction in the future. It possesses unparalleled strength, durability, and can be recycled infinitely, thus it is a key element for terawatt, low, carbon cities and infrastructure systems. By turning construction and infrastructure development to steel recycling, the industry can lighten its ecological footprint, save resources, regulate the expenses, and at the same time, provide structures that hold up over time. Steel recycling is more than just a support practice on the road to sustainable development; it is a primary strategy for the implementation of stronger, smarter, and more eco, friendly infrastructure.

Images- recyclingtoday.com, reclamet.co.uk

.png)