Glass Fiber-Reinforced Gypsum Overview

- Material & Composition: Glass Fiber-Reinforced Gypsum (GFRG) combines gypsum plaster with glass fibers, offering high strength, lightweight properties, and moldability for diverse architectural applications.

- Key Advantages: Provides durability, fire resistance, thermal insulation, acoustic benefits, dimensional stability, easy installation, and supports intricate designs.

- Applications: Widely used in wall & ceiling panels, columns, cornices, cladding, modular components, prefabricated domes, and vaults in residential, commercial, and institutional buildings.

GFRG is a composite material made out of a combination of gypsum plaster along with glass fibers. Such a combination helps improve the natural strength properties of gypsum plaster with retaining its ability to be molded easily along with keeping it lightweight in nature. GFRG is different from other materials like plaster or concrete because it possesses a higher strength-weight ratio.

This product is not only rugged but also very versatile. Whether it is used for wall panels and ceilings or more detailed architectural work such as domes, vaults, moldings, and cornices, GFRG offers great freedom of choice without necessarily sacrificing structural integrity. The many applications of GFRG are being witnessed not just in residential but also in commercial and institutional structures.

Increasing Relevance of GFRG

As the construction industry looks towards greener and more economical alternatives, GFRG emerges as one building material that fulfills two or more requirements together. Its ability to enhance construction speed, conserve materials, improve building safety, and boast unparalleled flexibility makes GFRG one of the most progressive materials in the industry today.

In addition, the fact that GFRG systems can easily adjust to both traditional and modern designs makes them applicable in all construction projects, regardless of size, ranging from high-rise residential and commercial buildings to restoration projects and large-scale infrastructural development.

Techniques for GFRG Production

The manufacture of GFRG product requires specific technologies that give the final part strength, accuracy, and useability. These are some of the common technologies used:

1. Spray-Up Technique

The Spray-Up process comprises applying a combination of gypsum plaster and glass fibers to a mold surface in a spray-gun manner. The process makes it possible to produce a large-sized component in a complex shape. The Spray-Up process is suitable for producing ceiling tiles and other ornaments which require a consistent thickness and strength.

2. Premix Method

The Premix process involves a mixture of gypsum and glass fibers in a dry form. The water is then introduced during this processing to make the plaster active, leading to a homogenous material. The above process is very ideal for mass production since it entails accurate control of material composition.

3. Continuous Filament Method

This process consists of passing continuous glass fibers through a gypsum slurry for regular coating, followed by the formation into the desired shape. The Continuous Filament method is specifically useful for the production of long GFRG elements-beams or profiles-where even reinforcement is an issue of strength and durability.

4. Pultrusion Method

Pultrusion is an efficient process wherein a mix of gypsum powder and glass fibers are pulled through a heated die at which they solidify into the specific shapes of rods, columns, or linear panels. This technique allows for production of reproducible items and is considered quite effective for creating those structural profiles that require consistency for strength.

Advantages of GFRG in Construction

GFRG has a combination of technical and aesthetic benefits which are unique and unrivalled:

- Resistant to cracking because it is reinforced with glass fibers. Glass fibers provide durability to GFRG by resisting

- Its density makes it less loaded structurally and thus suitable for use in ceilings and partitions.

- Provides inherent high-temperature resistance, making it safer in terms of building solutions

- Modular installation components ensure a smooth and simple installation process.

- Helps in energy conservation through thermal insulation.

- Enables the creation of very intricate designs right up to curved surfaces and architectural moldings.

- Resists variations in size due to environmental conditions.

- Provides sound insulation to improve the comfort level inside the building.

- Lightness in production also yields a reduced environmental footprint.

Types of GFRG Products and Their Applications

1. GFRG Wall Panels

One of the popular GFRG products is wall panels. They provide strength and aesthetic value to any structure. They can be installed indoors and outdoors for various purposes. The rigid sheets are quite easy to install. They can have intricate designs. They provide fire-resistance benefits along with easy-to-handle strength.

2. GFRG Ceiling Panels

Ceilings created by GFRG are lightweight, ornamental, and fire-resistant. These are appropriate for offices, shopping centers, hotels, hospitals, and residential structures and offer a seamless finish that imparts a superior interior design, besides acoustically insulating and energy-efficient.

3. GFRG

Being functional as well as aesthetically used, GFRG columns support load-bearing capabilities as well as allow architectural freedom in design. Beginning right from traditional architectural forms to minimalist designs, GFRG columns feature in a wide array of applications ranging from residential to commercial structures.

4. GFRG Cornice and Moldings

Cornices and moldings created using GFRG imitate intricate details of architecture and are much lighter in comparison to plasterwork. They are economical, easy to handle, and can be designed as per preference, making them popular among developers and designers wanting to add beauty to architecture.

5. GFRG Cladding

For external building facades, the use of cladding panels made of GFRG is beneficial in terms of durability and aesthetic appearance. This is because the panels can protect the building while offering very aesthetic looks.

6. GFRG Modular Components

GFRG modules, including shelving, niches, or panels in standard shapes, offer easy assembly work and ensure a uniform aesthetic. GFRG modules have been widely used in hotels, offices, or housing because they ensure faster assembly and uniformity.

7. Prefabricated GFR

Arches and domes can all be replicated by prefabricated structural elements, as they require a high level of precision in construction, precision that the elements can provide. Such structures include museums, churches, and skyscrapers.

8. GFRG Domes & Vaults

Such architectural designs as domes and vaults are enhanced by the beauty and strength provided by GFRG. Such designs are very useful in religious buildings, shopping centers, and atriums due to their portability and ability to load other architectural structures.

9. GFRG Boards

GFRG boards are thinner than regular panels and hence suitable for partitions and false ceilings. The boards offer all the advantages of lightweight construction technology, which is easy to install and provides a soundproofing feature as well.

Glass Fiber Reinforced Gypsum (GFRG) Market Pontial

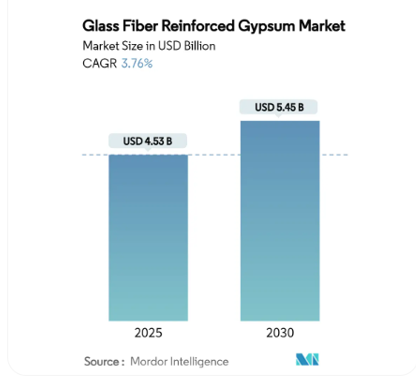

As per Mordar Intelligence report, the global Glass Fiber Reinforced Gypsum (GFRG) market is valued at USD 4.53 billion in 2025 and is forecast to reach USD 5.45 billion by 2030, growing at a CAGR of 3.76% during the forecast period. GFRG is increasingly adopted in modern construction due to its lightweight nature, superior fire resistance, durability, design flexibility, and faster installation compared to conventional gypsum boards and masonry systems.

Growth momentum is supported by tightening building safety regulations, rising emphasis on sustainable and low-carbon construction materials, and the construction industry’s need to reduce project timelines and labor dependency.

Key Market Drivers

Lower Installation and Life-Cycle Costs

GFRG panels weigh less than traditional gypsum boards, reducing structural load and enabling faster installation. This leads to lower labor costs, shorter construction cycles, and reduced long-term maintenance expenses. Retrofit and renovation projects particularly benefit, as GFRG can often be installed over existing surfaces without extensive structural reinforcement.

Stringent Fire-Safety Regulations

Global building codes increasingly mandate fire-rated wall and ceiling systems, especially in commercial, institutional, and high-rise residential buildings. Fire-rated GFRG boards meet 1-hour and 2-hour fire resistance requirements, driving consistent demand across hospitals, offices, airports, data centers, and public infrastructure.

Rising Demand for Premium Interior Aesthetics

Architects and designers prefer GFRG for curved walls, decorative ceilings, column casings, and custom architectural elements that are difficult and costly to achieve with conventional materials. Its smooth finish and low VOC emissions also support green building certifications such as LEED and WELL.

Sustainability and Resource Optimization

Manufacturers are using both natural gypsum and recycled flue-gas desulfurization (FGD) gypsum, aligning with circular-economy goals. GFRG’s lower embodied carbon compared to traditional materials strengthens its adoption in sustainability-focused construction projects.

Geographic Analysis

Asia-Pacific is the largest and fastest-growing region, holding 44.29% of global revenue and growing at 3.92% CAGR. Growth is driven by urbanization, infrastructure investment, and government housing initiatives in China, India, ASEAN countries, and Japan.

India Market Potential

The Indian Glass Fiber Reinforced Gypsum (GFRG) market holds great potential due to the increasing rate of urbanization in the country, along with government housing schemes (for example: Pradhan Mantri Awas Yojana) and the need for faster and more eco-friendly construction methods. GFRG is a lighter, fire-resistant, and ecologically friendly alternative to other construction materials available in the market, thus providing a cost-effective solution for the housing gap in India with great projected growth.

Key Growth Drivers:

Urbanization & Housing Requirements: When it comes to India, there is a huge demand for housing and rapid urbanization taking place, which requires methods that are very effective for rapid construction.

- Government Support: Programs related to providing affordable housing increase the usage of GFRG due to rapid construction completion.

- Sustainability: GFRG is recyclable and is a great example of a sustainable construction trend due to its energy efficiency.

- Efficiency: The prefabricated panels made of GFRG reduce construction time over RCC.

- Material Innovation:A better strength-to-weight ratio, fire-resistance property, and flexibility (lightweight and moldable).

GFRG / Glass Fibre Reinforced Gypsum Manufacturers & Suppliers

Primary GFRG Panel Manufacturers in India

- BACE India- Manufacturer of Glass Fibre Reinforced Gypsum (GFRG) wall panels and provider of GFRG-based construction solutions, including precast wall panels and green building systems.

- FACT – RCF Building Products Ltd. (FRBL), produces large GFRG panels using Rapidwall technology, originally developed in Australia.

Gypsum & Construction Material Suppliers (Supporting GFRG / GRG-based projects)

Although these companies may not manufacture GFRG panels directly, they supply gypsum boards, plaster of Paris (POP), ceiling tiles, drywall systems, and allied materials essential for gypsum-based construction.

Gypsum & Ceiling Material Suppliers

- Gypelite India Pvt. Ltd. – Gypsum products supplier

- Gypace India Gypsum Private Limited – Gypsum material supplier

- Global Gypsum Pvt. Ltd. – Gypsum products supplier

- Sky Gypsum – Gypsum product supplier

- Ceiling Hub Pvt. Ltd. – Gypsum ceiling product supplier

- Maruti Gypsum (Gyproc / Cement Sheet / Rockwool) – Gypsum and drywall solutions

- Balaji Gypsum Pvt. Ltd. – Gypsum product supplier with wide market reach

- Gypstar India Private Limited – Construction material wholesaler

- Arfa Traders (POP & Gypsum) – Retail supplier of gypsum products

- Saint-Gobain India Pvt. Ltd. – Gyproc Division – Manufacturer of gypsum boards, wall systems, and ceiling solutions

- Taparia Gypsum (India) – Gypsum manufacturing and supply

Specialty, Fibre-Reinforced & Composite Material Suppliers (Complementary to GFRG / GRG / Gypsum Construction)

These companies provide glass fibre, GFRP/CFRP systems, and composite reinforcement solutions used alongside gypsum-based construction, lightweight walling systems, and precast technologies.

Fibre-Reinforced Gypsum & Composite Solution Providers

- GRG Ceiling Tile- Supplier of Glass Reinforced Gypsum (GRG) ceiling tiles and decorative gypsum solutions for architectural and ceiling applications.

- Get FiBAR- Supplier of advanced composite and fibre-reinforced building materials supporting modern gypsum composite systems.

- Dextra India (Dextra Group)- Supplier of Glass Fiber Reinforced Polymer (GFRP) rebars, anchors, and reinforcement systems used in infrastructure and lightweight construction.

- Dharti Design & Decor- Distributor and supplier of KDMFIBER® glass fibers for concrete, plaster, and gypsum-based applications.

- Relinforce™ (Reliance Composites Solutions – Reliance Industries Ltd.) Manufacturer of Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) systems for structural strengthening and rehabilitation.

Conclusion

Glass Fiber, Reinforced Gypsum is not only a building material but also a breakthrough technology that combines engineering, design, and eco-friendliness. The uses of Glass Fiber, Reinforced Gypsum are so varied that they run from wall and ceiling panels to domes, vaults, and moldings, thus revealing it as a solution in modern construction.

The product is a great option for builders and designers who are seeking materials that are more efficient, environmentally sustainable, and aesthetically rich because of its light weight, fire, resistant properties, ease of installation and ability to be molded according to the project requirement, which is a mix of both functionality and creativity. In fact, GFRG is challenging the way we build by bringing innovation and art together, and it has a material that is going to shape the future of building design.

.png)