TMT bars, or Thermo-Mechanically Treated bars, are specialized steel reinforcement bars that undergo a unique treatment process. This results in a robust outer layer and a flexible core, combining high tensile strength with ductility. These properties enable TMT bars to support heavy loads while maintaining flexibility, which is particularly advantageous in earthquake-prone regions. TMT bars are widely utilized in construction due to their corrosion resistance, weldability, and elongation characteristics. Selecting the appropriate TMT grade, classified by tensile strength and flexibility, is crucial for ensuring structural safety and longevity based on specific project requirements.

Manufacturing Process of TMT (Thermo-Mechanically Treated) Bars

The TMT (Thermo-Mechanically Treated) bar manufacturing process involves the following steps:

1. Melting: Iron ore, coal, and limestone are melted in a blast furnace to produce molten steel.

2. Casting: The molten steel is cast into billets, cooled, and prepared for further processing.

3. Reheating: Billets are reheated to 1100-1200°C to soften them for shaping.

4. Hot Rolling: The reheated billets are rolled into bars of the desired diameter.

5. TMT Treatment:

- Quenching: Bars are rapidly cooled with water to harden the outer layer.

- Self-Tempering: Heat from the core tempers the surface for balanced strength.

- Cooling: Bars are cooled in air, forming a flexible yet strong core.

6. Quality Control: Bars undergo testing for tensile strength, corrosion resistance, and elongation.

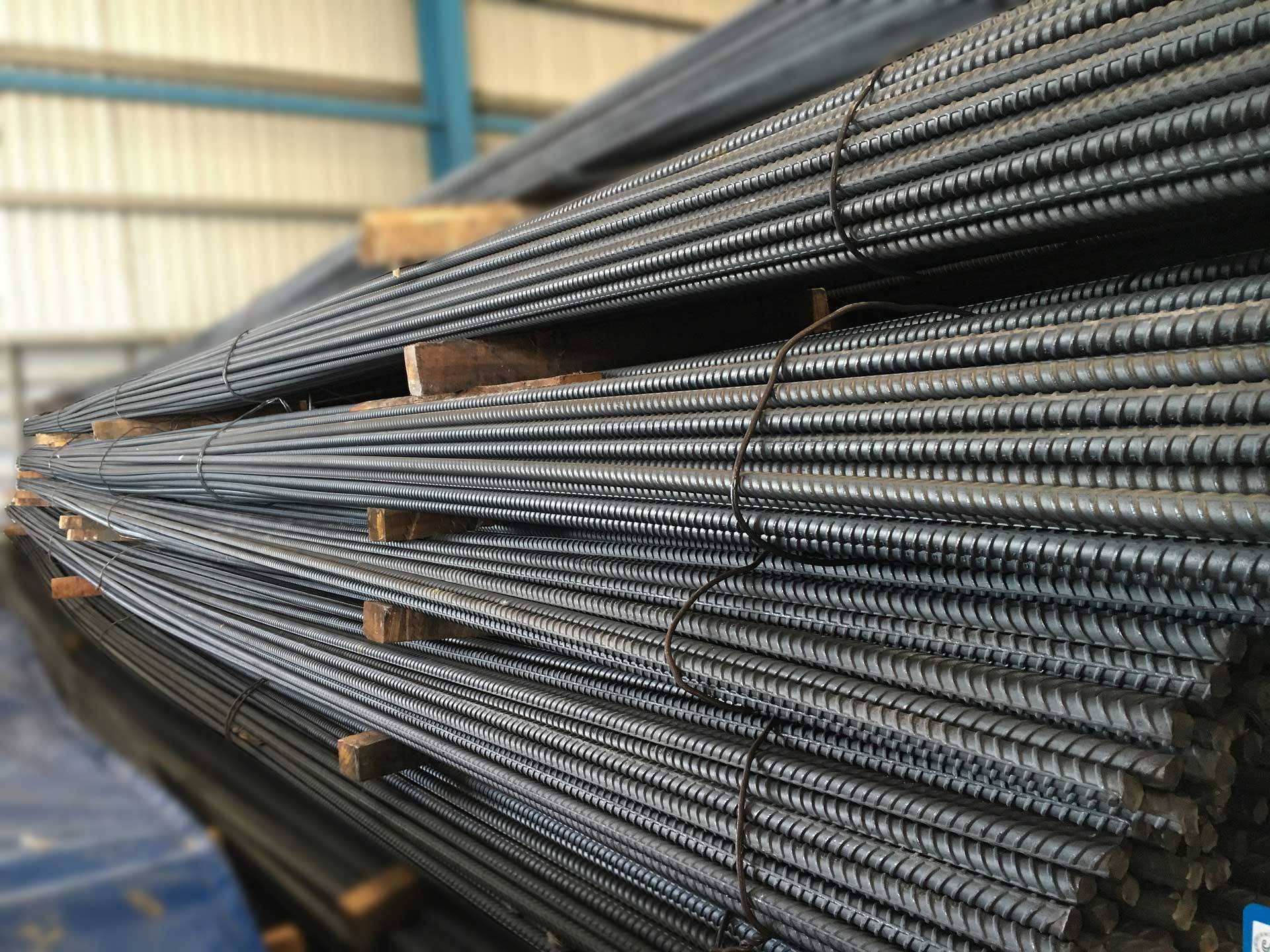

7. Finalizing: Bars are cut, bundled, and marked for shipment.

Advantages of TMT Bars

TMT bars offer numerous advantages that make them an optimal choice for reinforcing concrete structures:

High Strength and Ductility: The robust outer layer combined with a softer core gives TMT bars a high strength-to-weight ratio and flexibility, allowing them to withstand heavy stress while maintaining structural stability.

Corrosion Resistance: The treatments applied to TMT bars enhance corrosion resistance, crucial for projects in high-humidity or coastal regions.

Earthquake Resistance: The ductility of TMT bars enables them to absorb and redistribute stress, providing resilience during seismic events, making them ideal for earthquake-prone areas.

Fire Resistance: TMT bars can withstand high temperatures up to 600°C, offering added protection against fire hazards.

Cost-Effectiveness: With a high strength-to-weight ratio, TMT bars allow builders to use less steel, lowering material costs and making them a cost-effective choice for many construction projects.

Types of TMT Bars

Fe 415 TMT Bars

Fe 415 TMT bars are known for their ductility and cost-effectiveness, making them suitable for a variety of construction projects. With a minimum yield strength of 415 MPa, these bars are ideal for low-rise buildings and smaller-scale constructions. Their flexibility allows for easy bending, which is beneficial in budget-friendly projects. While Fe 415 bars offer good corrosion resistance, they are best suited for moderate environmental conditions, as they may not perform optimally in high moisture or saline environments.

Fe 500 TMT Bars

Fe 500 TMT bars are recognized as the industry standard, providing a balanced combination of strength and flexibility. With a yield strength of 500 MPa, these bars are versatile for both residential and commercial projects. Variants like Fe 500D enhance ductility for better performance in seismic zones, while Fe 500S is designed for enhanced seismic resistance. This grade is ideal for multi-story buildings and commercial complexes due to its ability to withstand higher stress levels and environmental challenges.

Fe 550 TMT Bars

Fe 550 TMT bars are designed for more demanding applications, offering a minimum yield strength of 550 MPa. They are particularly suited for infrastructure projects, such as bridges and highways, where load-bearing capacity is crucial. The enhanced corrosion resistance of Fe 550 bars makes them suitable for coastal and marine environments. Builders prefer this grade for its strength and reliability across various construction scenarios.

Fe 600 TMT Bars

Fe 600 TMT bars represent the highest grade, providing a yield strength of 600 MPa, making them ideal for heavy-duty applications. These bars are designed for large-scale industrial structures, metro systems, and expressways, where maximum tensile strength is essential. Fe 600 TMT bars reduce overall steel requirements, optimizing reinforcement layouts. Their advanced corrosion resistance ensures long-term performance even in harsh environments, making them suitable for demanding infrastructure projects.

Applications of TMT Bars

- Residential Construction

- Commercial Buildings

- Infrastructure Projects

- Coastal and Marine Structures

Market Potential and Demand of TMT Bars

According to Technavio report, the global TMT steel bar market is expected to grow by USD 85.9 billion at a CAGR of 4.26% from 2023 to 2028. This growth is primarily driven by the increasing demand for steel in infrastructure development and construction projects.

In India as per, Hindu report, India used 50.3 million tonnes of TMT bars in FY23, an increase from 46 million tonnes the previous year. Demand is projected to reach approximately 190 million tonnes by 2030, with the construction and infrastructure sectors accounting for 60-65% of total demand.

Several key factors drive the demand for TMT bars in India:

- Infrastructure and Construction Growth: Government initiatives like Smart Cities and affordable housing projects are fueling demand.

- Industrial Expansion: The growth of manufacturing and industrial sectors requires significant quantities of TMT bars for new facilities.

- Safety Standards: Increased awareness of structural safety necessitates high-quality TMT bars for durability, especially in earthquake-prone areas.

- Urbanization: Rising populations and a shift towards urban living create ongoing needs for housing and infrastructure.

Conclusion

TMT bars are integral to various construction projects, each benefiting from their unique properties. Selecting the appropriate TMT grade based on specific project requirements is essential for ensuring structural integrity and longevity. TMT bars provide strength, durability, flexibility, and resistance to environmental stresses, making them indispensable in modern construction.

Images- toptechtmt.com, .jswonemsme.com, srmbsteel.com

.png)