As the construction sector faces increasing pressure to reduce its environmental impact, attention is turning to concrete, one of the most commonly used building materials. Traditional concrete has been linked to high carbon emissions due to its primary ingredient, cement. In response to environmental concerns, low carbon concrete has emerged as an alternative. This material aims to meet the demand for sustainable construction while maintaining the necessary performance and durability.

Understanding Low Carbon Concrete

Low carbon concrete refers to concrete that is manufactured with a reduced carbon footprint compared to traditional concrete. Despite the reduction in emissions, low carbon concrete is designed to perform just like its conventional counterpart, ensuring that structural integrity and functionality are not compromised. This achievement is made possible through the use of alternative materials and production processes aimed at cutting down the carbon dioxide (CO2) emissions generated during its manufacture.

The main strategies for producing low carbon concrete include:

Utilizing Alternative Fuels: Concrete production relies heavily on energy-intensive processes, particularly in the manufacture of cement. By switching to alternative, low-carbon fuels such as renewable natural gas, waste biomass, or carbon-neutral fuels, the carbon footprint of concrete can be significantly reduced.

Incorporating Blended Cements: Traditional Portland cement is the most significant contributor to concrete's carbon footprint. By using blended cements that incorporate supplementary materials like fly ash, slag, or calcined clays, the need for cement is reduced, thus lowering emissions.

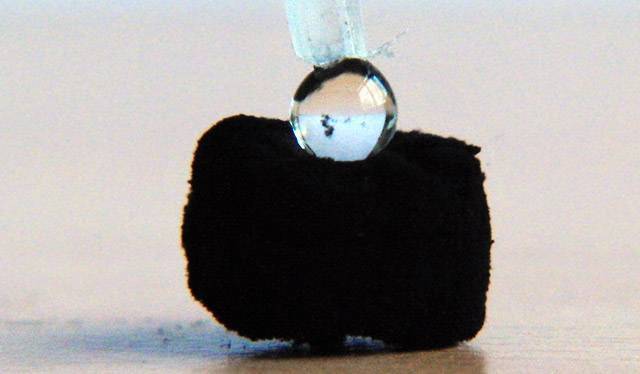

Implementing Carbon Capture Technologies: Carbon capture, utilization, and storage (CCUS) technologies capture the CO2 emissions produced during cement manufacturing. These emissions can be stored underground, reused to make concrete stronger, or even converted into useful products like synthetic aggregates.

Advantages of Low Carbon Concrete

- Low carbon footprint through reduced CO2 emissions in production.

- High durability and resistance to environmental wear and tear.

- Recycled aggregates and materials reduce waste and resource consumption.

- Energy-efficient production methods lower overall manufacturing energy use.

- Reduced Portland cement content, lowering carbon emissions.

- Maintains performance standards of traditional concrete.

Emerging Solutions of Low Carbon Concrete

Researchers are exploring a variety of innovative solutions aimed at lowering emissions in concrete production, particularly by finding alternatives to traditional cement. Below are some promising advancements in reducing the carbon footprint of concrete.

Limestone Calcined Clay Concrete (LC3)

Limestone Calcined Clay Concrete (LC3) is an exciting low-carbon alternative to traditional Portland cement. Developed by researchers from Switzerland and Cuba in 2005, LC3 can reduce emissions by up to 40%. It could prevent 500 million tons of CO2 emissions annually by 2030. LC3 uses calcined clays, limestone, and a small amount of clinker, offering a more energy-efficient method for cement production. The Cementos Argos plant in Colombia, which started production of LC3 in 2020, has achieved a 30% reduction in energy consumption and halved carbon emissions. Although scaling up LC3 production worldwide presents challenges, it holds the potential to become a dominant material in global cement production by 2050.

Bio-Cement

An innovative approach to reducing concrete’s carbon footprint involves using algae to create limestone through photosynthesis. This bio-cement process, developed by Wil Srubar at the University of Colorado Boulder, utilizes coccolithophores, a type of microscopic algae that sequesters carbon dioxide and stores it as limestone. The process is both carbon-neutral and potentially carbon-negative. While small-scale experiments have shown that algae-grown limestone blocks exhibit strength comparable to traditional concrete, scaling up the technology remains a challenge. Despite these hurdles, bio-cement could play a key role in reducing the carbon emissions associated with concrete in the future.

Electric Recycled Concrete

A groundbreaking innovation in concrete production comes from researchers at the University of Cambridge, who have developed an electric recycled cement process. This method uses electric arc furnaces (EAFs) to recycle cement waste and minimize the need for clinker, a key ingredient in concrete that contributes to emissions. By heating crushed concrete in EAFs, the slag produced mimics Portland cement, and this method has the potential to reduce emissions by up to 2 gigatons of CO2 annually. While still in the early stages, companies like Celsa Group are already testing the technology on a larger scale, aiming to produce up to 30 tons of recycled cement per hour. If powered by renewable energy, this process could revolutionize concrete production by significantly reducing emissions.

Startups Pioneering Low-Carbon Cement Technologies

Several startups are driving innovations that could transform the cement industry. Sublime, based in Massachusetts, employs an electrolytic process to convert limestone into lime, powered by renewable energy. Fortera, based in California, captures CO2 emissions from cement plants and reintegrates it into the production process to create low-carbon ReAct Cement™, reducing emissions by 70%. Another Californian company, Brimstone, uses calcium silicate rock instead of limestone to eliminate CO2 emissions during cement production. These startups are leading the charge with commercial-scale plants in the pipeline, pushing the envelope on sustainable alternatives in the cement and concrete industry.

Applications of Low Carbon Concrete Across Projects

Given below are few examples of low-carbon concrete been in projects used across the world.

1. Amazon HQ2, National Landing

Amazon's HQ2 project, part of the urban renewal efforts in National Landing, utilized over 106,000 cubic yards of concrete with CarbonCure technology, which injects CO2 into the concrete mix. This technology helped the project save more than 1,000 metric tons of CO2—equivalent to the carbon absorbed by 1,000 acres of forest in one year. CarbonCure enables the concrete to capture CO2 during production, permanently reducing the carbon footprint of the building materials.

2. Infosys Technology Hub, Indiana

For the Infosys Technology Hub in Indiana, 8,000 cubic yards of concrete were used, incorporating low-carbon mix designs. The mix utilized alternative materials, such as fly ash and slag cement, to minimize the carbon footprint. By reducing the amount of traditional Portland cement used, this approach helped Infosys reduce its carbon emissions and meet its sustainability goals, such as pollution prevention and long-term environmental stewardship.

3. The Edge, Amsterdam

The Edge in Amsterdam, known as one of the world’s most sustainable office buildings, used a combination of low-carbon concrete and recycled construction materials. The project utilized concrete mixes that incorporated recycled aggregates and industrial by-products like fly ash and slag cement. This helped reduce the overall carbon footprint of the building. The use of low-carbon concrete was part of a broader sustainability strategy that also included energy-efficient systems and smart building technologies.

4. King’s Cross Development, London

In London, the King’s Cross redevelopment utilized low-carbon concrete with recycled aggregates and alternative binders such as ground granulated blast furnace slag (GGBS), reducing the need for traditional Portland cement. The project poured a significant amount of concrete, contributing to an overall decrease in carbon emissions. The use of recycled materials helped cut emissions by a considerable margin, supporting the development’s commitment to sustainability.

5. Maggie’s Centre, London

At the Maggie’s Centre in London, low-carbon concrete was used, incorporating recycled materials and specially formulated mixes to reduce the environmental impact. The project used concrete containing recycled aggregates and other materials that allowed for a reduction in the overall carbon emissions from concrete production. The project aimed to create a sustainable healthcare facility while minimizing its carbon footprint.

Low Carbon Global Concrete Market Outlook

As per Data Intelo report, the global low carbon concrete market, valued at USD 15 billion in 2023, is projected to grow to USD 45 billion by 2032 at a CAGR of 13%. This surge is attributed to heightened environmental concerns, stricter carbon emission laws, and innovations in concrete manufacturing. Traditional concrete production contributes significantly to CO2 emissions, pushing industries and governments toward sustainable alternatives. Technological advancements have further enabled the creation of high-performance, eco-friendly concrete.

Demand for sustainable building materials is also rising, driven by rapid urbanization and infrastructure projects in emerging economies. Low carbon concrete meets green building standards, making it an attractive choice for architects, builders, and developers. This combination of environmental, regulatory, and technological factors is driving the market's robust growth.

The Way Forward

The growing environmental challenges in the construction industry have led to a shift towards low carbon concrete, which offers a sustainable alternative by reducing the carbon footprint of concrete production without compromising strength and durability. As the global market for low carbon concrete expands, driven by regulatory pressures and technological advancements, its widespread adoption is becoming essential. Projections show significant market growth, positioning low carbon concrete to play a pivotal role in shaping the future of sustainable infrastructure, helping the construction industry meet its environmental goals.

Image sources- rmi.org, poundfield.com, techxplore.com

.png)