GFRC is a specialized form of concrete that incorporates glass fibers as reinforcement. The fibers provide enhanced strength and durability compared to traditional concrete, which relies on steel reinforcement. GFRC’s composite structure consists of glass fibers dispersed throughout a cementitious matrix, resulting in a material that offers significant improvements in tensile strength, fatigue resistance, impact resistance, and durability. GFRC is lighter, thinner, and stronger than conventional concrete, making it suitable for architectural and structural applications that require both aesthetic appeal and functional performance.

Advantages of GFRC

The advantages of GFRC over traditional concrete are numerous, making it an ideal choice for various construction needs. Some of the key benefits include:

1. High Tensile Strength

GFRC provides superior tensile strength, exceeding that of steel reinforcement. This increased strength allows for thinner, lighter structures without compromising on performance. With a tensile strength of up to 4000 psi, GFRC is able to withstand greater stresses, making it ideal for load-bearing applications.

2. Lightweight and Easy to Handle

GFRC is much lighter than traditional concrete due to its thin sections and the reduced need for steel reinforcement. This lightweight property simplifies transportation and installation, reducing labor costs and minimizing the environmental impact associated with heavy materials. In some cases, GFRC can be up to 75% lighter than conventional concrete.

3. Design Flexibility

GFRC can be cast into virtually any shape, size, or texture, offering architects and designers unparalleled creative freedom. The material's flexibility allows it to mimic natural stone, wood, or other finishes, making it suitable for a variety of architectural and decorative applications.

4. Durability and Weather Resistance

One of the standout features of GFRC is its durability. The glass fibers enhance the material's resistance to cracking, shrinking, and environmental wear. GFRC also exhibits excellent resistance to freeze-thaw cycles, making it suitable for use in extreme weather conditions. Its resistance to water and moisture penetration further enhances its longevity.

5. Fire Resistance

GFRC is non-combustible, making it an ideal choice for applications that require fire resistance. It will not burn, providing an added layer of safety in fire-prone environments. This property makes GFRC particularly suitable for cladding and exterior panels.

6. Eco-Friendly

GFRC uses less cement than traditional concrete and often incorporates recycled materials, making it a more sustainable option. Its lightweight nature also reduces transportation energy, contributing to lower carbon emissions. Additionally, GFRC’s durability reduces the need for frequent replacements, further promoting sustainability.

7. Versatility in Application

GFRC can be used in a wide range of applications, including architectural cladding, decorative elements, structural components, and landscaping features. Its versatility allows it to be used in both new construction and renovation projects, making it a valuable material in modern architecture.

GFRC Manufacturing Processes

The production of GFRC involves several methods, each tailored to specific applications and project requirements. Below are some of the most commonly used manufacturing techniques:

1. Spray-Up Process

The spray-up process is one of the most popular methods for producing GFRC. In this process, the cementitious matrix is produced separately from the glass fibers. The fibers are cut within a specialized spray gun and mixed with the fluid concrete mixture as they are applied to the mold. This method allows for high fiber content and long fiber lengths, resulting in a strong, durable material. The spray-up process is ideal for creating large, complex shapes such as architectural panels and facade elements.

2. Pre-Mix Process

In the pre-mix process, the glass fibers are mixed with the cement matrix before being applied to the mold. This method is more versatile than the spray-up process, allowing for various production techniques such as casting, injection, vibration, and pressing. The pre-mix process can be further divided into sub-methods like spray premix, cast premix, pultrusion, and hand lay-up. Each of these techniques has specific applications based on the desired final product.

3. Hybrid Process

The hybrid process combines elements of both the spray-up and pre-mix processes. In this method, a thin face coat is sprayed onto the mold using a hopper gun, and then the fiber-loaded backer mixture is either poured or hand-packed behind the face coat. This process allows for precise control over the surface finish while maintaining the structural integrity provided by the fiber reinforcement.

4. Filament Winding Process

In the filament winding process, continuous strands of glass fiber are wound onto a mandrel and passed over round steel bars placed below the level of the mortar mix. This method is commonly used to produce unidirectional, cross-ply, or angle-ply laminates for specific applications such as pipes and cylindrical structures.

5. Filter-Press Process

The filter-press process is suitable for mass production of GFRC products with simple or complex shapes. A wet fibrous mix is produced with an excess of water, which is then pressed by a top plate to remove the excess water. This process is efficient for creating uniform, high-quality GFRC products with consistent strength and performance characteristics.

Applications of GFRC

GFRC is used in a wide range of applications where its unique properties—lightweight, strength, weather resistance, and design flexibility—make it an ideal material. Some common applications include:

1. Architectural Cladding- GFRC is widely used in architectural cladding due to its ability to mimic natural materials like stone or wood while offering superior performance. It is commonly used in building facades, spandrels, column covers, soffits, cornices, brackets, and quoins.

2. Landscaping and Hardscaping- GFRC is ideal for landscaping and hardscaping elements such as planters, bollards, urns, tables, benches, and fountains. Its durability and weather resistance make it a popular choice for outdoor applications.

3. Historical Restoration- GFRC is often used in historical restoration and renovation projects, where it can replicate intricate building ornaments made of materials like terra cotta, carved stone, or wood. Its lightweight nature makes it easier to install in restoration projects without compromising the structural integrity of the building.

4. Roofing and Windows- GFRC is also used in roofing and window components due to its lightweight and durable properties. Its resistance to moisture and environmental factors makes it a reliable material for these applications.

5. Bridges and Tunnels- In civil engineering, GFRC is used in the construction of bridges, tunnels, and other infrastructure projects. Its high strength-to-weight ratio and resistance to environmental wear make it a valuable material for these demanding applications.

6. Modular Buildings- GFRC's versatility and ease of use make it suitable for modular building components, such as precast panels, flooring, and foundations. Its lightweight nature allows for faster construction and reduced labor costs.

Growth of the Global Glass Fiber Market

As per Technavio report, the global Glass Fiber Market is projected to grow by USD 4.34 billion at a compound annual growth rate (CAGR) of 5.2% between 2023 and 2028. This growth is primarily driven by rising demand in the construction and transportation sectors, where lightweight yet durable materials are increasingly needed.

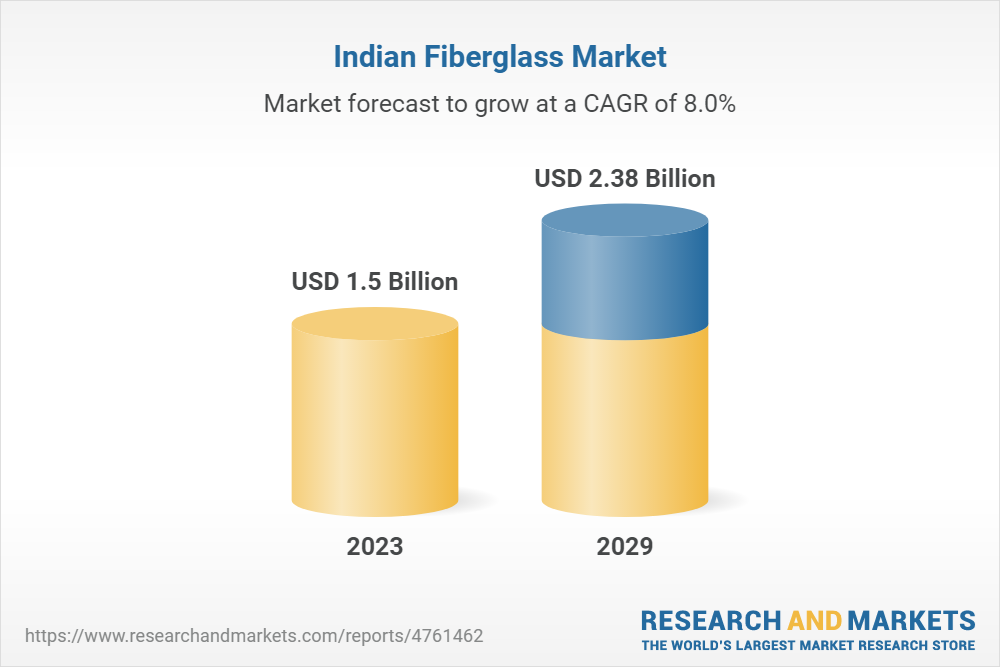

Expansion of the Glass Fiber Market in India

As per Research and Markets report, the glass fiber market in India was valued at approximately USD 1.5 Billion in 2023 and is expected to grow significantly, with a forecasted CAGR of 8.0% from 2023 to 2029. By 2029, the Indian market size is projected to reach around USD 2.38 Billion.

Conclusion

Glass Fiber Reinforced Concrete (GFRC) has become an essential material in modern construction due to its unique combination of strength, durability, and versatility. Its ability to be cast into a wide range of shapes and textures, combined with its high tensile and flexural strength, makes it a preferred choice for architects, engineers, and contractors alike.

Image sources-archdaily.com, aqso, sciencedirect.com

.png)