Bendable concrete, also known as ultra-ductile concrete (UDC) or engineered cementitious composite (ECC), represents a significant advancement in construction materials. Unlike conventional concrete, which is strong in compression but weak in tension and prone to cracking under stress, bendable concrete combines high tensile strength with remarkable flexibility. This innovative material can bend, stretch, and deform without fracturing, providing superior durability and resilience under dynamic loads, seismic events, and extreme environmental conditions. As infrastructure demands increase worldwide, bendable concrete is emerging as a sustainable and cost-effective solution for enhancing the longevity and safety of structures.

Addressing Crack Issue

Traditional concrete is a brittle material, which limits its structural performance in tension-prone applications. Cracking can occur due to shrinkage, thermal expansion, applied loads, or external forces, resulting in decreased durability, corrosion of reinforcement, and higher maintenance costs. Bendable concrete addresses these limitations through a combination of engineered fibers, optimized cementitious matrices, and advanced chemical admixtures.

Key Components of Bendable Concrete

- High-Performance Cementitious Matrix: A carefully formulated mix of cement, supplementary materials such as fly ash, silica fume, and fine aggregates, designed to enhance strength and ductility.

- Polymeric or Metallic Fibers: Fibers such as polyvinyl alcohol (PVA), polyethylene, or steel are dispersed throughout the matrix to control crack propagation, provide tensile strength, and enable energy absorption under stress.

- Chemical Admixtures: Superplasticizers, viscosity modifiers, and shrinkage-reducing agents improve workability, durability, and crack resistance.

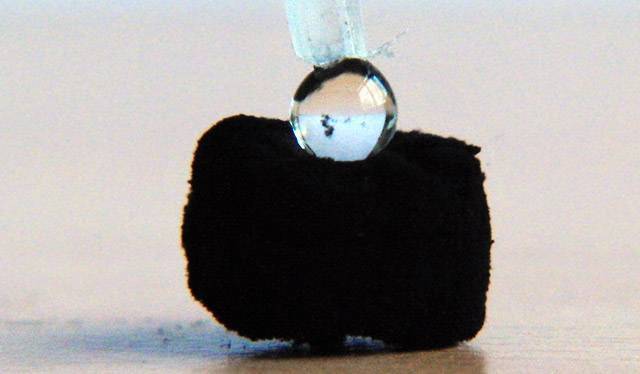

The combination of these components enables bendable concrete to undergo strain of up to 3–5%, compared to 0.01–0.1% in conventional concrete, without loss of structural integrity. Microcracks that form in bendable concrete are typically less than 100 micrometers wide and remain tightly controlled, preventing corrosion of reinforcement and water ingress.

Advantages of Bendable Concrete

Bendable concrete offers a range of advantages over conventional concrete, making it suitable for critical infrastructure and high-performance applications:

- Can withstand bending, stretching, and dynamic loads without fracturing.

- Microcracks remain tightly spaced and small, improving durability and reducing water penetration.

- Ideal for earthquake-prone regions, as it can absorb energy and deform without catastrophic failure.

- Longer service life and lower crack-induced repairs reduce overall maintenance expenditure.

- Controlled cracking prevents moisture from reaching embedded steel, limiting corrosion and extending structural longevity.

- Reduces the need for excessive reinforcement and repair, lowering the environmental impact of construction.

- Can carry higher bending loads than conventional concrete.

- Resists impact and dynamic stresses without sudden failure.

- Requires less reinforcement, reducing structural weight.

- Slows down crack growth, increasing structural lifespan.

- Maintains integrity under temperature variations and thermal stresses.

- Suitable for architectural or intricate infrastructure designs.

- Easily integrates with conventional concrete for retrofitting.

The unique properties of bendable concrete make it suitable for a variety of applications across infrastructure, commercial, and industrial projects:

- High-Rise Buildings: Columns, beams, and slabs constructed with bendable concrete exhibit enhanced tensile capacity and reduced susceptibility to microcracks.

- Seismic Zones: Critical infrastructure such as hospitals, schools, and emergency facilities benefit from bendable concrete’s earthquake resilience.

- Bridges and Flyovers: The material accommodates dynamic loads, vibrations, and expansion/contraction cycles, reducing fatigue and cracking.

- Pavements and Roadways: Flexible pavements can resist cracking caused by thermal expansion, heavy traffic, and environmental stresses.

- Marine and Coastal Structures: Its controlled microcracking and reduced permeability protect against chloride ingress and salt-induced corrosion.

- Water Retaining Structures: Dams, water tanks, and reservoirs benefit from its flexibility and tight crack control, reducing leakage and maintenance.

Technological Innovations in Bendable Concrete

Research and development have advanced the capabilities of bendable concrete, focusing on both performance optimization and large-scale implementation:

- Fiber Reinforcement Optimization: Studies on PVA, polyethylene, and hybrid fiber systems improve tensile strength and crack control. Optimal fiber length, diameter, and volume fraction are crucial for achieving maximum ductility.

- Engineered Cementitious Composites (ECC): ECC is a high-performance variant of bendable concrete with exceptional ductility, capable of sustaining multiple cracks while maintaining load-carrying capacity.

- Self-Healing Integration: Combining bendable concrete with self-healing technologies, such as bacteria or microencapsulated polymers, further enhances durability and reduces maintenance.

- Prefabrication Techniques: Bendable concrete panels and beams are being developed for modular construction, allowing faster deployment and reduced on-site labor.

- Additive Manufacturing: 3D printing of bendable concrete elements enables complex geometries and precise material placement, enhancing both architectural and structural design.

Implementations around the World

Several countries have successfully implemented bendable concrete in infrastructure projects, demonstrating its practical benefits:

- United States: The Federal Highway Administration has used bendable concrete in bridge deck overlays and pavements to reduce cracking and extend service life.

- Japan: Given its seismic activity, Japan has deployed bendable concrete in bridges, tunnels, and earthquake-resistant buildings to enhance structural resilience.

- China: Bendable concrete is being integrated into high-rise and coastal projects, improving resistance to dynamic loads and saltwater corrosion.

- Europe: Several pilot projects in Germany and the UK are testing ECC in public buildings and transportation infrastructure for energy absorption and crack control.

Research and Development in India

Indian universities and research institutions are conducting studies to understand and enhance the properties of bendable concrete. For instance, an experimental study demonstrated that ECC can withstand tensile strains of approximately 2.5% to 3% without failure, compared to traditional concrete, which fractures at much lower strains. This research highlights the superior flexural and compressive strength of bendable concrete as per ISJEM Journal.

Another study focused on the development of PVA (Polyvinyl Alcohol) fiber-reinforced ECC, emphasizing its potential to improve the strength, performance, and resilience of high-strength concrete. The research utilized linear regression to predict the strength of ECC at 28 days, showcasing its applicability in structural applications as per romanpub.com.

Researchers have conducted experimental investigations to assess the properties of bendable concrete. One such study explored the impact of incorporating polypropylene fibers into concrete, aiming to enhance its mechanical properties. The findings indicated that the addition of fibers improved the strength and durability of the concrete, making it more suitable for structural applications as per IJERT.

Challenges and Limitations

Despite its advantages, bendable concrete faces several challenges:

- Higher Initial Costs: The addition of fibers and chemical admixtures increases material costs compared to conventional concrete.

- Workability Concerns: Fiber dispersion must be carefully managed to avoid clumping, which can affect performance.

- Limited Awareness: Widespread adoption is slowed by the need for training and knowledge among engineers, contractors, and laborers.

- Long-Term Performance Data: While laboratory results are promising, extended field studies are necessary to validate performance under diverse environmental and loading conditions.

Future Outlook

Bendable concrete represents a significant breakthrough in construction technology, bridging the gap between strength and flexibility. By enabling structures to bend, deform, and resist cracking under stress, it extends the lifespan of buildings, bridges, roads, and marine structures while reducing maintenance and environmental impact. Although challenges such as cost, workability, and awareness remain, advances in material science, fiber reinforcement, and construction technology are poised to overcome these limitations. The integration of bendable concrete into high-performance infrastructure, seismic-resistant buildings, and sustainable urban development projects has the potential to reshape the way we design, build, and maintain modern structures, marking a major step forward in the evolution of construction materials.

.png)