Prefabrication construction can be defined as a type of construction where structural and non-structural portions are produced in a factory environment and then installed at the construction site. In conventional construction, most activities such as concrete casting, curing, and finishing are performed at the construction site; in prefabrication construction, most work is conducted off-site.

The prefabrication process would include processes such as designed prefabrication, prefabrication of the construction of buildings in factories, inspection of the prefabricated units to see the quality of the units, transportation of the prefabricated units, and the installation of the prefabricated units. The prefabricated units could include walls, slabs, beams, columns, staircases, roofs, or volumetric units.

Key System Types of Prefabricated Construction

1. Component-Based Prefabrication

Individual building components are separately prefabricated and then assembled on site in this system. Common components include:

- Precast concrete walls and slabs

- Steel Beams and Columns

- Staircases and façade panels

This approach allows partial prefabrication with retention of some flexibility from conventional construction.

2. Panelised Construction System

Panelized systems are the methods of assembling wall, floor, and roof panels in large sizes in factories. The panels may be provided with insulation, openings, and finishes. The panelized construction has been widely used in residential buildings, hotels, and institutional projects.

3. Volumetric or Modular Construction

Volumetric construction involves the off-site prefabrication of entire three-dimensional modules, such as rooms or apartment units. The modules are transported to site and stacked or joined to form complete buildings. The system offers maximum speed combined with quality control.

4. Hybrid Prefabrication System

Hybrid Systems combine the elements of prefabrication with conventional cast-in-situ construction. Examples are: slabs that are prefabricated with in situ topping of concrete, and modular bathrooms integrated into conventionally constructed buildings.

The Main Elements of Prefabricated Construction

Structural Elements

- Prefabricated columns & beams

- Wall panels (load-bearing and non-load-bearing panels

- Floor and Roof Slabs

Architectural & Functional details

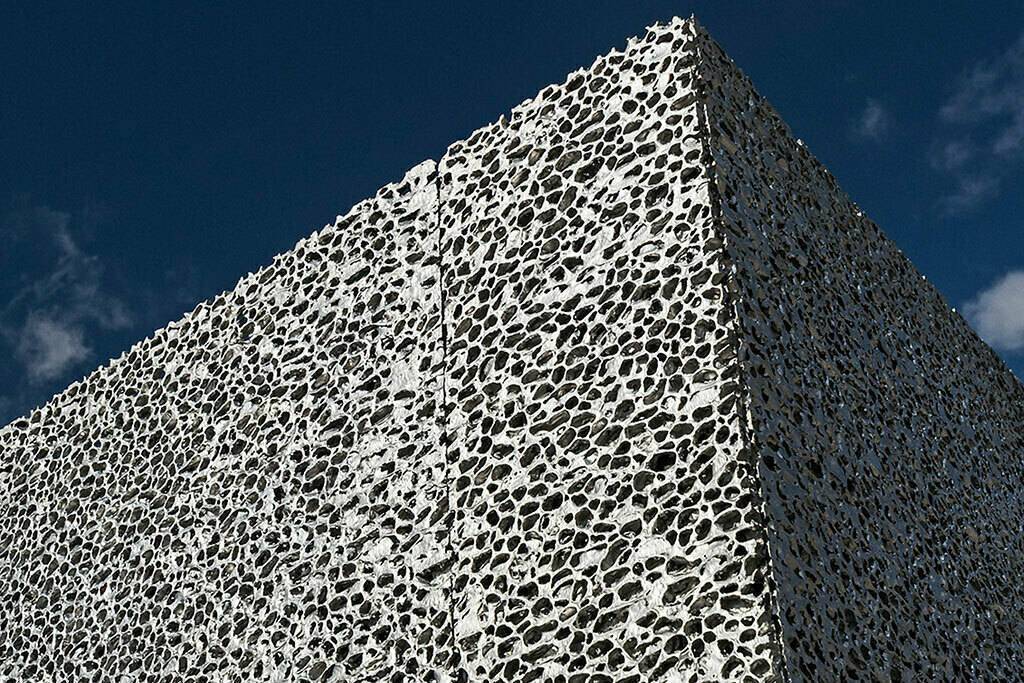

- Façade panels and cladding

- Staircases & Balcon

- Bathroom and kitchen modules

Connection and Jointing Systems

- Bolted and Welded Connections

- Grouted Joints And Sleeves

- Mechanical and Modular Connectors

Applications of Prefabricated Construction

1. Residential Buildings

Prefabricated construction is increasingly adopted in the:

- Mass housing projects

- High-rise residential buildings

- Student settlements and hostels

Repetition and standardization make residential projects ideal for prefabrication.

2. Commercial Buildings

- Office buildings and IT parks

- Hotels and serviced apartments

- Retail complexes and showrooms

3. Industrial and Logistics Facilities

- Warehouses and logistic parks

- Manufacturing plants and factories

- Cold storage facilities

4. Infrastructure Projects

- Metro and railway stations

- Bridges and flyovers

- Utility buildings and service structures

5. Institutional and Social Infrastructure

- Hospitals and healthcare facilities

- Schools and educational campuses

- Government and defense buildings

Advantages of Prefabricated Construction

- Rapid Construction Schedules- Simultaneous off-site construction and foundation construction can shrink the length of projects from 30-60 percent.

- Enhanced Quality & Precision-Factory-controlled production will ensure quality and dimensions as well as superior finish.

- Lower Labour Dependence- Prefabrication reduces on-site manual labours, thereby mitigatingasons related to lack oflabour productivity.

- Cost Efficiency and Predictability- Rework, materials waste, and timelines are reduced. Overall, there are improved economics of the project.

- Increased Safety- Controlled environments in factories and fewer site operations result in a reduced number of accidents and improved safety.

- Benefits of Sustainability- Less construction waste, Reduces dust, noise, and water consumed on site

India’s Prefab Construction Market Potential and Key Drivers

As per KPMG report, The market potential for prefabricated construction in India is substantial and largely untapped. Despite accounting for just 1–2 per cent of the overall infrastructure market today, prefab is poised for exponential growth as policy, technology and demand converge. With India’s infrastructure sector projected to touch USD 323 billion by 2029, even a modest increase in prefab adoption to 5–7 per cent could unlock a multi-billion-dollar opportunity over the next decade. The segment’s expected growth to USD 5.47 billion by 2030 is only an early indicator of its long-term potential.

Several structural drivers are accelerating this shift. . Government initiatives such as the PMAY, GATI Shakti, Smart Cities, and large-scale development of industrial corridors require pace, standardization, and quality, wherein prefabs score high. However, with increased labour gaps, cost of materials, and short execution schedules, there is an increased thrust from developers and construction companies to adopt industrialized construction. Sectors such as budget housing, warehouses, data centers, healthcare, and education infrastructure are some of the initial adopters herein.

Second, the need for sustainable solutions is gaining prominence. With the adoption of net-zero goals and sustainable urbanization in India, the fact that prefab solutions are environmentally friendly, minimizing wastage, cutting down greenhouse gas emissions, as well as enhancing energy efficiency, makes it the ‘future-proof’ answer. Greater private investment in this sector, flexibility in designing, and the right government policies are needed for prefab construction to shift from the sidelines to the main foundation of the infrastructure story in India in 2047.

According to the report by Mordar Intelligence, “The market value of prefabricated buildings in India was USD 15 billion in 2025 and is projected to reach USD 35.1 billion by 2030 at a CAGR of 8.80% during the forecast period (2025 – 2030). This growth represents the extent to which the maturing supply chain, government policies, and digital manufacturing are turning the economics and timescales of the existing construction paradigm upside down. Federal government housing subsidies of USD 64.6 billion, the increasingly long data-center pipeline, and the enforcement of energy codes provide the steady demand driver. Developers are focusing on 5% to 6% time-saving benefits, suppliers are spending on robotic production facilities that reduce waste by 20%, and the currently fragmented market is increasingly consolidating to accommodate companies that are able to marry the need to reduce greenhouse gas emissions to zero by 2050 with the need to maintain costs under control. Barriers to entry remain manageable but are rising. Success is dependent on the avoidance of the estimated 45,000-worker gap in the currently successful skills agenda.”

Main Market Driving Forces

Speed and Efficiency

One of the most potent factors fueling the use of prefabrication is its capacity to improve construction times. Factory-controlled manufacturing, simultaneous site work, and fast assembly rates work well to reduce the effects of weather and labor and material inefficiency. This factor remains highly important in the context of commercial and industrial projects and infrastructure.

Affordable Housing and Government Plans

Prefab construction can very well meet the specifications of the flagship government schemes like Pradhan Mantri Awas Yojana (PMAY) and Smart Cities Mission, which emphasize the need for speed, scalability, and economy. This is because prefab constructions promote components manufacturing on a mass scale, less material wastage, and less labor dependence.

Infrastructure Development and Urbanization

Rapidly growing urbanization in India and its needs in the form of infrastructure development, including transport facilities, healthcare institutions, and educational infrastructure, are triggering a greater adoption of prefab construction. The process ensures effective quality and timely completion, which is required for meeting the challenging infrastructure development schedules.

Market Trends & Material Evolution

Currently, concrete-based prefab structures occupy the majority of the market because of their structural strength, adaptability, and suitability as per Indian requirements. Notwithstanding, engineered wood is turning out to be the fastest-growing category because of its adaptability and sustainable development needs. Steel-based construction, such as PEB and LGS, remains popular in industrial and commercial construction.

Technology adoption and adoption of technology such as Building Information Modeling, automation, and project management technology is showing improvement in design intensity and efficiency. The industry is also undergoing consolidation, with large-capacity and technology-driven companies displaying scale advantages.

Prefabricated and Modular companies in India

- ACE Prefab is a well-recognized manufacturer of prefabricated structures, PUF panels, and modular buildings for offices, laboratories, storage units, and utility areas.

- Synergy Prefab India specialises in the supply and erection of modular and prefabricated steel structures, site offices, clean rooms for healthcare and pharmaceutical facilities, housing, and commercial buildings.

- Modern Prefab Systems Pvt. Ltd. serves as one of the leaders within the fields of prefabricated and pre-engineered buildings, right from design to fabrication and onto site installation for the industrial, infrastructure, and transit projects.

- Aaks Architecture is a consulting design firm that caters to modular and prefabricated building systems, offering cost-effective and sustainable solutions across residential, commercial, and industrial markets.

- Shilpkar India provides pre-engineered and prefabricated building solutions, offering turnkey services ranging from structural steel systems to insulated panels and customised building packages.

- Patel Infraa provides a range of fabricated products including portable cabins, prefab homes, security cabins, and labour accommodation units.

- MK Prefab Private Limited is a manufacturer and supplier of prefabricated structures for industrial, commercial, and residential purposes, assuring the usage of rapid deployment with durability.

- Pressmach Infrastructure provides engineering, procurement, and commissioning services related to the prefabrication of buildings, including designing, manufacturing, site planning, and installation of modular structures for various industries.

- Indue PreFab is involved in the light gauge steel framing technology used for residential sectors, warehouses, schools, hospitals, and institutional buildings.

- SimplyPrefab provides prefabricated and modular construction options with ISO certification for warehouses, industrial units, and multi-story prefab construction projects.

Modular & Off-site Construction Specialists

- KEF Infra is known for its off-site construction and modular construction technology in residential, healthcare, and commercial projects.

- Magicrete Building Solutions specializes in precast and prefabricated construction systems in large-scale residential as well as commercial projects.

- Champion Infratech provides container-based modular houses, offices, as well as customized buildings.

- Aap Ka Awas LLP (IHS-One) provides modular and hybrid prefabricated housing solutions that would include solutions based on government-approved construction technology.

- Epack Prefab Technologies Limited specializes in engineering, fabrication, and project management, offering comprehensive pre-engineered building solutions.

Pre-Engineered Building and Structural System Suppliers

- Kirby Building Systems is one such large pre-engineered building producer catering to industrial, warehousing, and infrastructure applications.

- Tata BlueScope Steel provides pre-engineered building systems for industrial and commercial construction.

- Zamil Steel India offers steel building systems widely used in prefabricated and modular construction works.

Future Outlook

The Prefabricated construction methods are likely to be at the forefront in the future construction landscape. With the construction industry embracing industrialized and technology-driven construction methods, prefabrication will no longer remain in niche segments but become mainstream in residential and commercial construction as well as infrastructure development projects.

Prefab construction signals a paradigm shift with regard to building design, construction, and delivery processes and procedures. Since prefab construction tackles various shortcoming confronted by traditional construction techniques with regard to speed, quality, safety standards, costs, and sustainability factors, prefabricated construction is all set to become one of the key elements of construction processes in the future due to increased demands for urban and infrastructure development.

Images-technologycards.net, constructionsport.com, epack.in

.png)