With the global drive towards sustainable development and energy efficiency, the building industry is increasingly looking at advanced materials to reduce energy consumption. Aerogel insulation, known for its ultra-lightweight, thermally resistant properties, is an innovative material offering incredible insulation with a thin profile.

What is Aerogel?

Aerogels, first developed in the 1930s and further researched in the 1980s and 1990s with the advent of carbon aerogels, are low-density, solid-state materials known for their unique structure and properties. Often called "liquid smoke" due to their translucent appearance and light scattering, aerogels are made by replacing the liquid in a gel with gas, preserving the original structure while drastically reducing density. This is achieved through supercritical drying, which removes the liquid in a way that avoids collapsing the solid framework They can be made from various precursors, including silica, carbon, polymers, and even metals like gold and copper. With up to 99.8% of their structure composed of air, aerogels are among the lightest and most efficient insulating materials available.

Advantages of Aerogel Insulation:

Aerogel insulation has several significant benefits over traditional insulation materials:

- Provides high thermal insulation, effectively reducing heat transfer.

- Lightweight structure, with up to 99.8% of its composition as air.

- Allows for space-saving with thinner layers offering effective insulation.

- Naturally hydrophobic, resists moisture while allowing vapor to escape.

- Thin profile provides high efficiency, ideal for confined spaces.

- Durable and long-lasting, maintaining insulation properties over time.

- Non-combustible, adding reliable fire resistance to applications.

- Usable across diverse industries, including construction and energy.

- Reduces noise transmission, providing effective acoustic insulation.

- Functions well in extreme temperatures, suitable for harsh environments.

Types of Aerogel Products for Buildings

Aerogel insulation products come in several forms, each designed to serve a particular purpose in for buildings

1. Aerogel Granules

Aerogel granules are small, loose particles that can be mixed into plaster or other materials to enhance thermal insulation. They are often used as a cavity filler in double-wall construction or added to concrete mixtures to create lightweight, insulating building blocks. These granules improve insulation without adding much weight, making them suitable for retrofitting older structures where structural integrity may be a concern.

2. Aerogel Blankets

Aerogel blankets consist of flexible, fabric-like materials infused with aerogel particles, which maintain high insulation performance while being easy to handle and install. They are ideal for insulating irregular or curved surfaces such as pipes, HVAC ducts, or arched walls, where traditional rigid insulation panels would be challenging to fit. These blankets are highly effective in reducing heat transfer in tight spaces and are commonly applied in areas like attics and between floors for under-floor heating systems.

3. Aerogel Boards

Aerogel boards are rigid, durable panels made by combining aerogel particles with a supporting material to form a solid board. These boards are easy to cut and install, making them ideal for walls, floors, and ceilings, where they offer significant thermal insulation with minimal thickness. They are commonly used in high-performance residential and commercial buildings, where energy efficiency is prioritized without compromising interior space.

4. Aerogel Panels

Designed specifically for translucent applications, aerogel panels are made to enhance both insulation and light transmission. These panels are especially suitable for windows, skylights, and glass facades where daylight is desired but heat loss needs to be minimized. The combination of insulation with natural light makes aerogel panels a sustainable choice for commercial and residential buildings aiming to reduce artificial lighting costs and improve energy efficiency.

5. Aerogel Concrete

Aerogel concrete integrates aerogel granules into traditional concrete to create a lightweight, insulating concrete mix. This type of concrete is well-suited for building facades and exterior cladding, where it provides thermal protection while also reducing the overall weight of the structure. In addition, aerogel concrete has excellent sound insulation properties, making it valuable in urban construction where noise reduction is needed.

6. Aerogel Coatings and Plasters

Aerogel-based coatings and plasters are liquid or semi-liquid applications that can be applied to existing surfaces to enhance their thermal insulation. These coatings are particularly beneficial in renovation projects, where adding insulation to walls, ceilings, or other surfaces without a significant thickness increase is required. Aerogel coatings can be applied like traditional paint, making them a convenient solution for adding insulation to existing buildings or hard-to-reach spaces.

Applications of Aerogel Insulation in Sustainable Building Construction

- Walls and Exterior Insulation: enhance insulation in both new builds and retrofits.

- Roofs and Attics: provide high-efficiency insulation with minimal space usage.

- Window and Door Frames: reduce air leakage and improve thermal efficiency around openings.

- High-Efficiency Windows: used in multi-pane windows to enhance insulation while maintaining natural light.

Global and Indian Aerogel Market Outlook

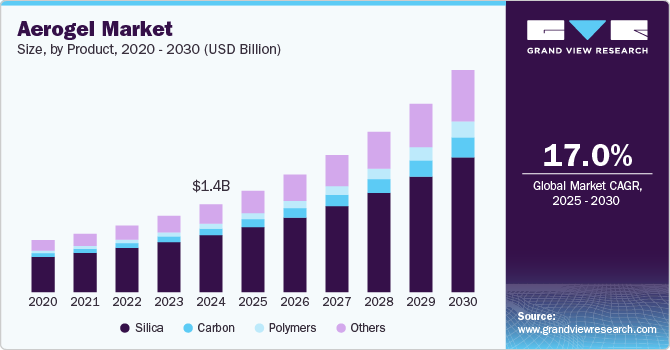

As per Grand View Research, the global aerogel market, valued at approximately USD 1.38 billion in 2024, is expected to register a compound annual growth rate (CAGR) of 17.0% from 2025 to 2030. This growth is driven by the increasing demand for energy-efficient solutions in industries and construction as global energy consumption continues to rise.

As per TechSci Research, in India, the aerogel market is projected to grow at a CAGR of 5.38% from 2023 to 2029. The demand for aerogel products is fueled by government initiatives promoting energy efficiency and sustainability, along with rising energy prices that encourage industries and consumers to seek more energy-efficient solutions. Aerogel’s high-performance thermal insulation is particularly valuable in reducing heating and cooling costs in buildings, aligning with India’s focus on energy conservation and sustainability.

Manufacturers and Suppliers of Aerogel Products in India

Several manufacturers and suppliers are playing a pivotal role in meeting the growing demand for aerogel products in India, especially in the construction and industrial sectors

- Aspen Aerogels (via distributors) – Offers Pyrogel® and Cryogel® for industrial and construction insulation.

- Cabot Corporation (via distributors) – Supplies Lumira® aerogel for building applications and energy-efficient insulation.

- Armacell India – Provides ArmaGel HT, used for high-temperature industrial and construction insulation.

- Thermablok India – Specializes in aerogel strips for reducing thermal bridging in buildings.

- Enersys – Supplies aerogel blankets and panels for energy efficiency in construction and industrial projects.

- Aerogreen Insulation Pvt. Ltd. – Offers aerogel blankets and panels for building and industrial insulation.

- Va-Q-tec (via distributors) – Provides vacuum insulation panels incorporating aerogel for energy-efficient buildings.

Conclusion

Aerogel insulation is becoming a key material in modern construction due to its exceptional thermal resistance, lightweight properties, and long-lasting durability. As the demand for high-performance, energy-efficient solutions grows, aerogel's innovative applications are set to play an important role in advancing sustainable building practices.

Images-tchaintech.com, indiamart.com

.png)